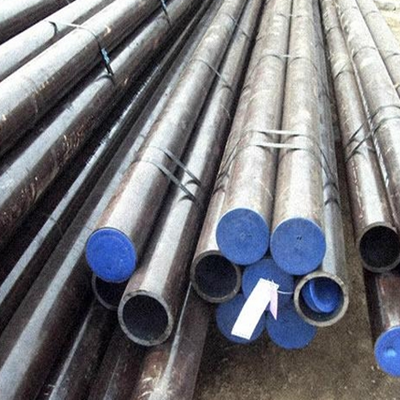

ASTM A333 Grade 10 Low-Temperature Seamless Steel Pipe

- ASTM A333/ASME SA333

- China

- Stock,Production

- Grade 10

ASTM A333 Grade 10 Steel Pipe is suitable for -45 ~ -195 ~ C low temperature pressure vessel pipes and seamless steel tubes for low temperature heat exchanger pipes.

ASTM A333 Grade 10 Low-Temperature Seamless Steel Pipe

ASTM A333 Grade 10 Low-Temperature Seamless and Welded Steel Pipe

ASTM A333 Grade 10 is a grade of ASTM A333 Standard.ASTM A333/A333M-16 Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness.

ASTM A333 Grade 10 Steel Pipe is suitable for -45 ~ -195 ~ C low temperature pressure vessel pipes and seamless steel tubes for low temperature heat exchanger pipes.

We can customize and innovate the ASTM A333 Grade 10 Low-Temperature Steel Pipe with advanced technology. Our all ASTM A333 Grade 10 Steel Pipes are tested in accordance to internationally recognized standards or our own more stringent internal test procedures, which is developed considering the harsh field conditions. Tension test, flattening test, flaring test, hardness test, hydrostatic or nondestructive electric test be made on specimens.

ASTM A333 Grade 10 Low-Temperature Seamless and Welded Steel Pipe Quick Details

Company Name: beite steel pipe

Country/Region: China

Product Name:ASTM A333 Grade 10 Steel Pipe

FOB Price: US $1300-2600 / Ton | 1 Ton/Tons (Min. Order)

Port of Shipment:Tianjin,China

Payment:L/C or T/T

Delivery: 7-15 days after payment

Package:Standard export package,suit for all kinds of transport, or as required.

ASTM A333 Grade 10 Steel Pipe Dimensional Range & Specification

Outside Diameter:20 – 215mm

Wall thickness:2mm——15mm

Length:6000mm、12000m or specified length as required.

Materials and Manufacture

Manufacture—The pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation.

For the seamless process only, reheat and control hot working and the temperature of the hot-finishing operation to a finishing temperature range from 1550 to 1750°F [845 to 945°C] and cool in air or in a controlled atmosphere furnace from an initial temperature of not less than 1550°F [845°C].

Heat Treatment:

Normalize by heating to a uniform temperature of not less than 1500°F [815°C] and cool in air or in the cooling chamber of an atmosphere controlled furnace,reheat to a suitable tempering temperature.

For the seamless process only, reheat and control hot working and the temperature of the hot-finishing operation to a finishing temperature range from 1550 to 1750°F [845 to 945°C] and cool in air or in a controlled atmosphere furnace from an initial temperature of not less than 1550°F [845°C].

Seamless pipe of Grades 10 may be heat treated by heating to a uniform temperature of not less than 1500°F [815°C], followed by quenching in liquid and reheating to a suitable tempering temperature

The test pieces shall be gradually and uniformly heated to the prescribed temperature, held at that temperature for a period of time in accordance with Table 1, and then furnace cooled at a temperature not exceeding 600°F [315°C]. Grade 8 shall be cooled at a minimum rate of 300°F [165°C]/h in air or water to a temperature not exceeding 600°F [315°C].

Table 1 Stress Relieving of Test Pieces

| Metal Temperature (A , B) |

Minimum Holding Time, h/in. [min/mm] of Thickness |

|

| Grades 10 | ||

| °F | °C | |

| 1100 | 600 | 1 [2.4] |

| 1050 | 565 | 2 [4.7] |

| 1000 | 540 | 3 [7.1] |

Chemical Composition(%) & Physical Properties of ASTM A333 Grade 10 Steel Pipe

ASTM A333 Grade 10 Steel Pipe Chemical Composition(%)

| Steel Grade | Chemical Composition(%) | ||||||||||||

| C | Mn | P | S | Si | Ni | Cr | Cu | Al | V | Nb | Mo | ||

| Grade 10 | ≤0.20 | 1.15-1.50 | ≤0.035 | ≤0.015 | 0.10-0.35 | ≤0.25 | ≤0.15 | ≤0.15 | ≤0.06 | ≤0.12 | ≤0.05 | ≤0.05 | |

When Grades 10 are ordered under this specification, supplying an alloy grade that specifically re- quires the addition of any element other than those listed for the ordered grade in Table 1 is not permitted. However, the addition of elements required for the deoxidation of the steel is permitted.

Product Analysis

At the request of the purchaser, an analysis of one billet or two samples of flat-rolled stock from each heat or of two pipes from each lot shall be made by the manufacturer. A lot of pipe shall consist of the following:

| NPS Designator | Length of Pipe in Lot |

| Under 2 | 400 or fraction thereof |

| 2 to 6 | 200 or fraction thereof |

| Over 6 | 100 or fraction thereof |

Mechanical Properties

Tensile Requirements

| / | Grade 10 | |

| / | Ksi | Mpa |

| Tensile strength, min | 80 | 550 |

| Yield strength, min | 65 | 450 |

| Longitudinal | Transverse | |

| Elongation in 2 in. or 50 mm, (or 4D), min, %: | ||

| Basic minimum elongation for walls 5⁄16 in. [8 mm] and over in thickness, strip tests, and for all small sizes tested in full section | 22 | ..... |

| When standard round 2-in. or 50-mm gage length or proportionally smaller size test specimen with the gage length equal to 4D (4 times the diameter) is used | 16 | ..... |

| For strip tests, a deduction for each 1⁄32 in. [0.8 mm] decrease in wall thickness below 5⁄16 in. [8 mm] from the basic minimum elongation of the following percentage | 1.25B | ..... |

| Wall Thickness | Elongation in 2 in. or 50 mm, min, %C | ||

| Grade 10 | |||

| in. | mm |

Longi- tudinal |

Trans- verse |

| 5⁄16 (0.312) | 8 | 22 | .... |

| 9⁄32 (0.281) | 7.2 | 21 | .... |

| 1⁄4 (0.250) | 6.4 | 20 | .... |

| 7⁄32 (0.219) | 5.6 | 18 | .... |

| 3⁄16 (0.188) | 4.8 | 17 | .... |

| 5⁄32 (0.156) | 4 | 16 | .... |

| 1⁄8 (0.125) | 3.2 | 15 | .... |

| 3⁄32 (0.094) | 2.4 | 13 | .... |

| 1⁄16 (0.062) | 1.6 | 12 | .... |

B The following table gives the calculated minimum values.

C Calculated elongation requirements shall be rounded to the nearest whole number.

Note:The preceding table gives the computed minimum elongation values for each 1⁄32in. [0.80mm] decrease in wall thickness. Where the wall thickness lies between two values shown above, the minimum elongation value is determined by the following equation:

| Grade | Direction of Test | Equation |

| 8 | Longitudinal | E = 40t + 9.50 [E = 1.56t + 9.50] |

|

where: E = elongation in 2 in. or 50 mm, in %, and t = actual thickness of specimen, in. [mm]. |

||

Impact Requirements

For Grades 10 the notched-bar impact properties of each set of three impact specimens, including specimens for the welded joint in welded pipe with wall thicknesses of 0.120 in. [3 mm] and larger, when tested at temperatures in conformance with 14.1 shall be not less than the values prescribed in Table .

TABLE Impact Requirements for Grades 10

| Size of Specimen, mm | Minimum Average Notched Bar Impact Value of Each Set of Three SpecimensA | Minimum Notched Bar Impact Value of One Specimen Only of a SetA | ||

| ft·lbf | J | ft·lbf | J | |

| 10 by 10 | 13 | 18 | 10 | 14 |

| 10 by 7.5 | 10 | 14 | 8 | 11 |

| 10 by 6.67 | 9 | 12 | 7 | 9 |

| 10 by 5 | 7 | 9 | 5 | 7 |

| 10 by 3.33 | 5 | 7 | 3 | 4 |

| 10 by 2.5 | 4 | 5 | 3 | 4 |

Workmanship, Finish and Appearance

The pipe manufacturer shall explore a sufficient num- ber of visual surface imperfections to provide reasonable assurance that they have been properly evaluated with respect to depth. Exploration of all surface imperfections is not required.

Surface imperfections that penetrate more than 12½ % of the nominal wall thickness or encroach on the minimum wall thickness shall be considered defects.

Mechanical Testing

Sampling—For mechanical testing

Transverse or Longitudinal Tensile Test and Flattening Test

Hydrostatic Test—Each length of pipe shall be sub- jected to the hydrostatic test.

Impact Test

Impact Tests (Welded Pipe)—On welded pipe

Impact Test

Except when the size of the finished pipe is insufficient to permit obtaining subsize impact specimens, all material furnished to this specification and marked in accordance shall be tested for impact resistance at the minimum temperature for the respective grades as shown in Table .

ASTM A333 Grade 10 Steel Pipe Impact temperature

| Steel Grade | Impact temperature | ||||||||||||

| ℉ | ℃ | ||||||||||||

| Grade 10 | -75 | -60 | |||||||||||

Hydrostatic or Nondestructive Electric Test

Product key description, this is a very good product description, detailing our product use, product characteristics