- EN 10216-2

- China

- Stock

- 13CrMo4-5

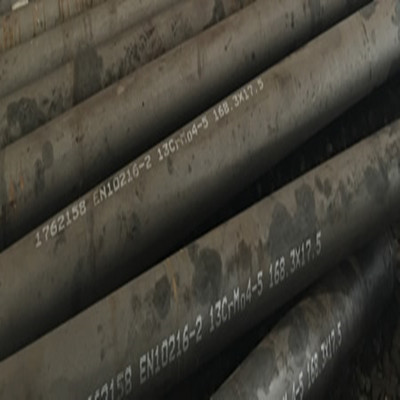

EN 10216-2 13CrMo4-5 Seamless steel tubes for pressure purposes.Seamless steel tubes for pressure purposes —Technical delivery conditions.Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10216-2 13CrMo4-5 Seamless Steel Tubes

EN 10216-2 13CrMo4-5 Seamless Steel Tubes

Standard:EN 10216-2

Seamless steel tubes for pressure purposes —Technical delivery conditions

Part 2: Non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10216-2 13CrMo4-5 Seamless steel tubes for pressure purposes

EN 10216-2 13CrMo4-5 Seamless steel tubes Quick Details

Manufacture:Seamless process

Wall thickness(WT): 2.1mm——20 mm.

Outer diameter (OD): 21 mm——509mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished (Outside only) to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

The steel name of non-alloy steel grades

(1)The capital letter P for pressure purposes;

(2)The symbols GH for elevated temperature.

MANUFACTURING PROCESS

(1)Steel making process

Steels shall be fully killed.

(2)Tube manufacture and delivery conditions

The tubes shall be manufactured by a seamless process.

The tubes can be either hot or cold finished.

EN 10216-2 13CrMo4-5 Seamless steel tubes shall be supplied in the relevant heat treatment conditions as specified in Table 1.

| Steel grade |

Heat treatment a |

Austenizing | Tempering | |||

|

Steel name |

Steel number |

Temperature °C |

Cooling Medium |

Temperature °C |

Cooling medium |

|

| 13CrMo4-5 | 1.7335 | +NT b c | 900 to 960 | Air | 680 to 750 | air |

Chemical composition of EN 10216-2 13CrMo4-5

| Steel grade | Steel number | C | Si | Mn | P max | S max | Cr | Mo | Ni | Al tot | Cu |

| 13CrMo4-5 | 1.7335 | 0,10 to 0,17 | ≤ 0,35 | 0,40 to 0,70 | 0,025 | 0,020 | 0,70 to 1,15 | 0,40 to 0,60 | ≤ 0,30 | ≤ 0,040 | ≤ 0,30 |

Mechanical properties of EN 10216-2 13CrMo4-5

| Steel grade | Upper yield strength or proof strength R eH or Rp 0,2 for Wall Thickness Tmin. |

Tensile Strength Rm |

Elongation A min. % a |

|||||

| Steel name |

Steel number |

T ≤ 16 | 16 < T ≤ 40 | 40 < T ≤ 60 | 60 < T ≤ 100 | l | t | |

| MPa * | MPa * | MPa * | MPa * | MPa * | ||||

| 13CrMo4-5 | 1.7335 | 290 | 290 | 280 | - | 440 to 590 | 22 | 20 |

Dimensions tolerances of EN 10216-2

Tolerances on outside diameter and wall thicknes

| Outside Diameter D mm |

Tolerances on D |

Tolerances on T for a T/D ratio | |||

| ≤ 0,025 |

> 0,025 ≤ 0,050 |

> 0,050 ≤ 0,10 |

> 0,10 | ||

| D ≤ 219,1 |

± 1% or ± 0.5mm whichever is the greater |

± 12,5% or ± 0.4mm whichever is the greater | |||

| D > 219,1 | ± 20% | ± 15% | ± 12,5% | ± 10% a | |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | |||||

Tolerances on inside diameter and wall thickness

| Tolerances on inside diameter | Tolerances on T for a T/d ratio | |||||

| d | d min | ≤ 0,03 |

> 0,03 ≤ 0,06 |

> 0,06 ≤ 0,12 |

> 0,12 | |

| ± 1% or ± 2 mm whichever is the greater |

(+ 2% ,0)or (+ 4 mm,0) |

whichever is the greater | ± 20% | ± 15% | ± 12,5% | ± 10% a |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | ||||||

Tolerances on outside diameter and minimum wall thickness

| Outside diameter D mm | Tolerances on D | Tolerances on T min for a T min /D ratio | |||

| ≤ 0,02 |

> 0,02 ≤ 0,04 |

> 0,04 ≤ 0,09 |

> 0,09 | ||

| D ≤ 219,1 |

± 1% or ± 0.5mm whichever is the greater |

(+ 28%,0) or (+ 0.8 mm,0) whichever is the greater | |||

| D > 219,1 |

+ 50% 0 |

+ 35% 0 |

+ 28% 0 |

+ 22% a 0 |

|

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | |||||

Tolerances on inside diameter and minimum wall thickness

|

Tolerances on inside diameter |

Tolerances on T min for a T min /d ratio |

|||

| d | d min | ≤ 0,05 |

> 0,05 ≤ 0,1 |

> 0,1 |

|

± 1% or ± 2 mm whichever is the greater |

(+2%,0) or (+ 4 mm,0) whichever is the greater |

+ 35% 0 |

+ 28% 0 |

+ 22% a 0 |

| a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5% of the wall thickness T | ||||

Tolerances on exact lengths

Dimension in mm

| Length L | Tolerance on exact length |

| L ≤ 6000 |

+10 0 |

| 6000 < L ≤ 12 000 |

+15 0 |

| L > 12 000 |

+ by agreement 0 |

TESTINGS

(1)Chemical analysis

(2)Tensile test(Tensile test at room temperature, Tensile test at elevated temperature)

(3)Flattening test

(4)Ring tensile test

(5)Drift expanding test

(6)Ring expanding test

(7)Impact test

(8)Leak tightness test(Hydrostatic test, Electromagnetic test)

(9)Dimensional inspection

(10) Visual examination

(11) Non-destructive testing

MARKING

Marking to be applied

The marking shall be indelibly marked on each tube at least at one end. For tubes with outside diameter D ≤ 51 mm the marking on tubes may be replaced by the marking on a label attached to the bundle or box.

PROTECTION

The tubes will be delivered with A temporary protective coating or durable coating and/or lining

Ordering Information

Mandatory information

a) the quantity (mass or total length or number);

b) the term "tube";

c) the dimensions ;

d) the designation of the steel grade in accordance with this Part of EN 10216 ;

e) the test category for non-alloy steel .

Options

1) Cold finishing.

2) Restriction on copper and tin content.

3) Product analysis.

4) Impact testing .

5) Longitudinal impact testing at -10° C for non-alloy steel grades.

6) Tensile testing at elevated temperature .

7) Selection of leak-tightness test method .

8) Non-Destructive Testing for test category 2 tubes for detection of transverse imperfections.

9) Non-Destructive Testing for test category 2 tubes for detection of laminar imperfections .

10) Special ends preparation.

11) Set of dimensions other than D and T.

12) Exact lengths ).

13) The type of inspection document other than the standard document.

14) Test pressure for hydrostatic leak-tightness test .

15) Wall thickness measurement away from the ends .

16) Non-Destructive Testing method.

17) Additional marking .

18) Protection .

Product key description, this is a very good product description, detailing our product use, product characteristics