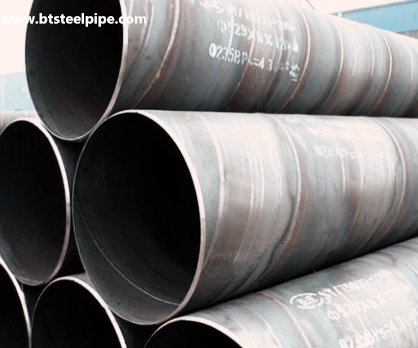

ASTM A381 Y52 Metal-Arc-Welded Steel Pipe

ASTM A381 Y52 Metal-Arc-Welded Steel Pipe Standard:ASTM A381 Standard Specification for Metal-Arc-Welded Steel Pipe for Use With High-Pressure Transmission Systems ASTM A381 Y52 Metal-Arc-Welded Steel Pipe are intended for fabrication of fi

ASTM A381 Y52 Metal-Arc-Welded Steel Pipe

ASTM A381 Y52 Metal-Arc-Welded Steel Pipe

Standard Specification for

Metal-Arc-Welded Steel Pipe for Use With High-Pressure Transmission Systems

ASTM A381 Y52 Metal-Arc-Welded Steel Pipe are intended for fabrication of fittings and accessories for compressor or pump-station piping.

ASTM A381 Y52 Metal-Arc-Welded Steel Pipe covers straight seam, double-submerged-arc-welded steel pipe suitable for high-pressure service, 16 in. (406 mm) and larger in outside diameter, with wall thicknesses from 5 ⁄ 16 to 1 1 ⁄ 2 in. (7.9 to 38mm).

ASTM A381 Y52 Metal-Arc-Welded Steel Pipe Quick Details

Company Name: Beite steel pipe

Country/Region: China

Product Name:ASTM A381 Y52 Metal-Arc-Welded Steel Pipe

Manufacture:Metal-Arc-Welded .

Outside Diameter:406-1011mm

Wall thickness:7.9mm——38mm

Length:6000mm、12000m or specified length as require

Port of Shipment:Tianjin,China

Payment:L/C or T/T

Delivery: 7-15 days after payment

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden)

Materials and Manufacture

The steel plate used in the manufacture of the pipe shall be of suitable welding quality carbon steel

Heat Treatment:

All pipe, after welding, ASTM A381 Y52 Metal-Arc-Welded Steel Pipes are heat treated at a temperature of 1100°F (593°C) or higher.

When specified in the purchase order, all pipe after welding shall be heated at 1650 to 1750°F (899 to 954°C) and air cooled.

Chemical Composition

| Element | Composition, %, max | |

| Ladle | Check | |

| Carbon | 0.26 | 0.30 |

| Manganese | 1.40 | 1.50 |

| Phosphorus | 0.025 | 0.030 |

| Sulfur | 0.025 | 0.025 |

Mechanical Properties

| Class |

Yield Strength, min, psi (MPa) |

Tensile Strength, min, psi (MPa) |

Elongation in 2 in. (50.8 mm),min, % |

| Y 52 | 52 000 (360) | 66 000 (455) | 20 |

Mechanical Tests

Transverse Body Tension Test

Transverse Weld Tension Test

Transverse Guided-Bend Weld Test

Hydrostatic Test

Radiographic Examination

We will employ radiography as a production control on the welding employed in the manufacture of pipe to this specification.

Permissible Variations in Dimensions

Outside Diameter—60.5 % of the specified outside diameter for the outside diameter based on circumferential measurement, except that in sizes 24 in. (610 mm) and smaller this tolerance shall be 6 1 ⁄ 8 in. (3.2 mm).

Out-of-Roundness—1 %, that is, the difference between the major and minor outside diameter.

Thickness—The minimum wall thickness shall not be more than 0.01 in. (0.25 mm) under the specified thickness. Localized (isolated and noncontinuous) reductions in wall thickness caused by noninjurious surface defects may be permitted up to a depth not exceeding 6 1 ⁄ 2 % the specified pipe wall thickness.

Ends

The width of the end is 1 ⁄ 16 in. (1.6 mm) with a tolerance of 6 1 ⁄ 32 in. (0.8 mm).

The end of the pipe is not be out of square more than 1 ⁄ 16 in. (1.6 mm).

Ordering Information

1 Orders for material include the following, as required, to describe the desired material adequately:

1.1 Quantity (feet, centimetres, or number of lengths),

1.2 Name of material (metal-arc welded pipe),

1.3 Class (Y52),

1.4 Material (carbon or alloy steel),

1.5 Size (outside diameter and wall thickness),

1.6 Length (specific or random) ,

1.7 Ends ,

1.8 Heat treatment (stress-relieved or normalized) ,

1.9 Specification number, and

1.10 Special requirements or exceptions to this specification.

Product key description, this is a very good product description, detailing our product use, product characteristics