- A213,A312 etc

- China

- Stock

- Sanicro 25

Sanicro 25 steel (also known as alloy 174) is a new type of high-temperature steel with excellent multi-component composite strengthening, high temperature performance and oxidation / corrosion resistance.

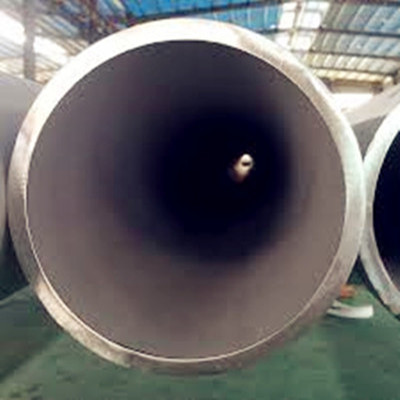

Sanicro 25 austenitic heat resistant steel tubes

Sanicro 25 austenitic heat resistant steel tubes

Sanicro 25 steel

Sanicro 25 steel (also known as alloy 174) is a new type of high-temperature steel with excellent multi-component composite strengthening, high temperature performance and oxidation / corrosion resistance, which is developed on the basis of traditional austenitic heat-resistant steel, adding W, Co, Cu, B and other elements, combining solid solution strengthening with C, n, Co, W and other elements, and precipitation strengthening with Nb (C, n), nbcrn, M23C6 and Cu rich phase Cr, Ni austenitic heat-resistant steel.

At present, sanicro 25 steel has been listed in vdtuv555 material list of Germany and ASME SA213m of 2010 version, and its UNS number is S31035

Sanicro 25 austenitic heat resistant steel tubes Quick Details

Manufacture:Seamless process

Specification:63.5mm*10.5mm, 70mm*15mm

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

Chemical composition of Sanicro 25

| Grade | C | Mn | Si | P | S | Cr | Ni |

| Sanicro 25 | 0.04-0.10 | ≤0.60 | ≤0.40 | ≤0.030 | ≤0.015 | 21.5-23.5 | 23.5-26.5 |

| Cu | Nb | N | W | Co | B | ||

| 2.0-3.5 | 0.30-0.60 | 0.15-0.30 | 2.0-4.0 | 1.0-2.0 | 0.002-0.008 | ||

In sanicro 25 steel, the improvement of high-temperature strength is mainly achieved by solution strengthening of C, N, CO and W elements, and precipitation strengthening of Nb (C, n), nbcrn, M23C6 and Cu rich phase; in order to improve high-temperature corrosion resistance, high Cr content and average value are adopted to reach 22.5%, but in order to inhibit the tendency of ∂ phase produced by high Cr and W, Ni content is increased to about 25% and N content is also high; at the same time, Ni content is increased to about 25% and N content is also high Its Mn and Si are controlled at a low level.

Heat treatment and organization

According to ASME SA213, the supply state of sanicro 25 steel is solution treatment. After solution treatment at 1180-1250 ℃, the microstructure is austenite (grain size is 7 or coarser), containing some precipitates rich in Nb and Cr.

Mechanical property of Sanicro 25

| Grade | Tensile strength(Mpa) | Yield strength(Mpa) | Elongation | HBW/HV/HRB |

| Sanicro 25 | ≥515 | ≥205 | ≥35 | ≤192/200/90 |

Mechanical properties at high temperature and short time

| Temperature(℃) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

| Tensile strength(Mpa) | ≥625 | ≥575 | ≥560 | ≥550 | ≥535 | ≥500 | ≥455 | ≥355 |

| Yield strength(Mpa) | ≥250 | ≥225 | ≥210 | ≥200 | ≥195 | ≥180 | ≥180 | ≥180 |

Process performance

Sanicro 25 steel has excellent processing properties such as welding and forming, which is also one of the important competitive factors in the application of sanicro 25 steel in boiler engineering projects.

Welding performance: sanicro 25 steel can be welded by TIG welding without preheating before welding and post welding heat treatment. Like most high alloy austenitic steels, welding surfaces and wires need to be cleaned. In order to avoid the existence of thermal cracks, the low heat input and the temperature between the bottom layers (< 100 ℃) can be used, and the restraint stress can be avoided.

Bend performance: sanicro 25 steel can be used for cold bending and hot bending.

Cold bending: when the working temperature is in the creep temperature range and the cold bending is more than 20%, solution treatment is required. Of course, in order to ensure good corrosion resistance at high temperature, solution is also suitable for small deformation.

Hot bending: the recommended temperature is 850-1250 ℃. Among them, when the deformation temperature is 850-1180 ℃, solution treatment should also be carried out; when the temperature range of hot bending is controlled between 1180-1250 ℃, solution can not be re solved.

Application prospect

Superheater and reheater are the key parts of boiler. Their high temperature endurance, high temperature resistance to steam oxidation and corrosion resistance are very important, which directly affect the efficiency and safety of boiler.

Sanicro 25 steel has many advantages compared with austenitic heat-resistant steel such as Super304H, HR3C and another important material nf709, which are widely used at present

(1) Higher high temperature endurance strength can effectively reduce the wall thickness of steel pipe and the overall weight of boiler;

(2) Good resistance to steam oxidation, can reduce oxide skin peeling, avoid oxide skin blocking the pipeline, improve the efficiency and safety of boiler operation, and prolong the life of boiler;

(3) Excellent corrosion resistance.

Therefore, the application of sanicro 25 steel tube in the heating surface of super critical boiler, such as superheater and reheater, does have a certain prospect, but it depends on the price of raw materials, the manufacturing of power equipment and the recognition of sanicro 25 by the power industry.

Product key description, this is a very good product description, detailing our product use, product characteristics