GB/T 5312 Grade 490 Carbon Seamless Steel Pipe

- GB/T 5312

- China

- Stock

- 320, 360, 410, 460, 490, etc.

GB/T 5312 Grade 490 seamless steel pipes are applicable to the manufacture of Class I pressure piping systems for ships, Class II pressure piping systems, carbon steel and carbon manganese steel seamless steel tubes for boilers and superheat

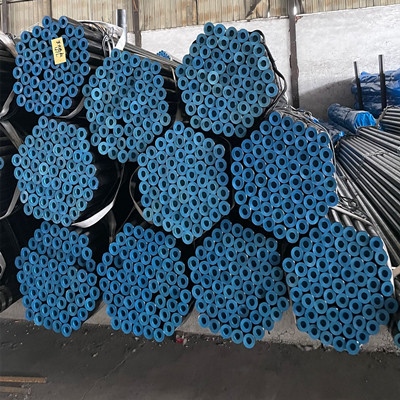

GB/T 5312 Grade 490 Carbon Seamless Steel Pipe

GB/T 5312 Grade 490 Carbon Seamless Steel Pipe

Grade 490 is a grade of GB/T 5312 standard,GB/T 5312 Grade 490 seamless steel pipes are applicable to the manufacture of Class I pressure piping systems for ships, Class II pressure piping systems, carbon steel and carbon manganese steel seamless steel tubes for boilers and superheaters.

GB/T 5312

Carbon steel and carbon-manganese steel seamless steel pipe for ships,This standard specifies the classification, code, size, shape, weight, technical requirements, test methods, inspection rules, packaging, marking and quality certificates of carbon steel and carbon-manganese steel seamless steel tubes (hereinafter referred to as steel pipes) for ships.

GB/T 5312 Grade 490 Carbon Seamless Steel Pipe Quick Details

Type:Seamless Steel Pipe.

Material:Grade 490.

WT:4-21mm.

OD:21-508mm

Length:6M or specified length as required.

Ends:Plain End、Beveled End、Treaded

FOB Price: US $700-1400 / Ton | 1 Ton/Tons (Min. Order)

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished (Outside only) to prevent rust.

Marking:Standard + Steel Grade + Size + Heat No + Lot No

Package:Standard export package,suit for all kinds of transport, or as required

Mechanical Properties of GB/T 5312 Grade 490 Carbon Seamless Steel Pipe

Chemical Composition of GB/T 5312 Grade 490 carbon seamless steel pipe

Note: Residual elements Cr≤0.25%, Mo≤0.10%, Ni≤0.30%, Cu≤0.30%, total ≤0.70%

| Standard | Grade | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) |

| GB/T5312 | 490 | 490~610 | ≥285 | ≥21 |

Chemical Composition of GB/T 5312 Grade 490 carbon seamless steel pipe

| Standard | Grade | Chemical composition(%) | ||||

| C | Si | Mn | P | S | ||

| GB/T5312 | 490 | ≤0.23 | ≤0.35 | 0.80~1.50 | ≤0.035 | ≤0.030 |

Size tolerance

| Steel pipe | Outer diameter (OD) | Wall thickness(WT) | ||

| Cold drawn pipe | Outer diameter(mm) | tolerance | wall thickness(mm) | tolerance |

| >30~50 | ±0.3 | ≤30 | ±10% | |

| >50~219 | ±0.8% | |||

| Hot rolled pipe | >219 | ±1.0% | >20 | ±10% |

Tests and Inspection

Tension test,

Flattening test,

Flaring test,

Hardness test,

Hydrostatic or nondestructive electric test

Flattening test,

Flaring test,

Hardness test,

Hydrostatic or nondestructive electric test

Product key description, this is a very good product description, detailing our product use, product characteristics