- GB/T 1299

- China

- Stock

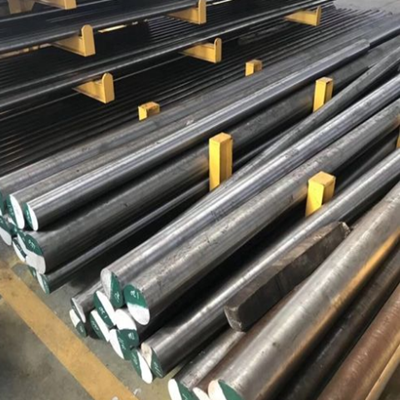

- Cr12MoV Steel

Cr12MoV Steel Alloy tool steel: Cr12MoV Cr12MoV Alloy tool steel, the hardenability of steel, quenching and tempering hardness, wear resistance, and strength are all higher than Cr12. Various cold-punching dies and tools with complex shapes

Cr12MoV Steel

Cr12MoV Steel

Alloy tool steel: Cr12MoV

Cr12MoV Alloy tool steel, the hardenability of steel, quenching and tempering hardness, wear resistance, and strength are all higher than Cr12. Various cold-punching dies and tools with complex shapes and heavy working conditions, such as punching dies, trimming dies, hemming dies, steel deep drawing dies, circular saws, standard tools and gauges, thread rolling dies, etc.

Chinese name: Cr12MoV

Foreign name: x165crmow12ku

Standard: GB/T 1299-2000

Scope of application: cold work mold

Hardness: 255 ~207HBW

Indentation diameter: 3.8 ~4.2mm

Scope of application

Cold work die steel, the hardenability of steel, quenching and tempering hardness, wear resistance, and strength are all higher than Cr12. Used to manufacture various cold punching dies and tools with large cross-sections, complex shapes and heavy working conditions, such as punching dies, trimming dies, hemming dies, deep drawing dies for steel plates, circular saws, standard tools and gauges, Thread rolling die, etc.

Availability

Supply varieties include hot-rolled materials, forging materials, cold-drawn materials, hot-rolled steel plates and cold-drawn steel wires

Equivalent grade

| GB | CNS | EN | DIN | JIS | KS | UNI | ASTM |

| cr12mov | skd11 | 1.2601 | x165crmov12 | skd11 | STD11 | x165crmow12ku | x12m |

Chemical composition of Cr12MoV

|

Grade |

Chemical composition | |||||||||

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | V(%) | Cu(%) | |

| Cr12MoV | 1.45~1.70 | ≤0.40 | ≤0.40 | ≤0.030 | ≤0.030 | 11.00~12.50 | ≤0.20 | 0.40~0.60 | 0.15~0.30 | ≤0.30 |

Mechanical properties of Cr12MoV

Hardness: Annealing, 255~207HB (14-25BRC), indentation diameter 3.8~4.2mm; quenching, ≥60HRC

Heat treatment specification

Heat treatment specification: 1. Quenching, 950~1000℃ oil cooling; 2. Quenching 1020℃, tempering at 200℃ for 2h.

Metallographic structure: fine-grained pearlite + carbide.

Delivery status: The steel is delivered in annealed condition.

Specification for softening of cold extrusion mold

The iron filings are protected and heated, the temperature is 760~780°C, the time is 10h, the furnace is cold, the hardness is l96HBW, and the cold extrusion can be smoothly realized

Ordinary isothermal spheroidizing annealing specification

850~870℃×3~4h, cooling with the furnace to 740~760℃×4~5h isothermal, air cooling hardness ≤241HBW, eutectic carbide grade ≤3, the best isothermal temperature 740~76o°C, time ≥4 ~5h

Spheroidizing annealing specification

(860±1ü)°C×2~4h, furnace cooling at 30°C/h cooling rate, (740±10)°c x 4-6h, slowly cooling with the furnace to 500~600°C, and air cooling after the furnace. Hardness 207 ~255HBW.

Cryogenic treatment

Crl2MoV steel undergoes cryogenic treatment, which can precipitate highly dispersed ultra-fine carbides from the quenched martensite, which can be transformed into carbides after subsequent low-temperature tempering at 200°C. Martensite without cryogenic treatment, after low-temperature tempering, only a small amount of carbides are precipitated in some local areas. Crl2MoV adopts low temperature chemical heat treatment method. On the basis of maintaining high hardness and high wear resistance of Crl2MoV steel, ion nitriding, gas nitrocarburizing, and salt bath thiocyanate co-infiltration are commonly used in low temperature chemical heat treatment. The three low-temperature chemical heat treatment infiltration layers have significant impact resistance and adhesion, and the salt bath thiocyanate co-infiltration is the best. After the Crl2MoV steel stainless steel utensil drawing mold is treated by gas nitrocarburizing, the service life is more than 30,000 pieces, which is more than 10 times longer than that of similar molds with conventional quenching and tempering treatment.

Hardened

In order to increase the die life to more than 800,000 die times, the pre-hardened steel can be hardened by quenching and low temperature tempering. When quenching, preheat at 500-600°C for 2-4 hours, then keep it at 850-880°C for a certain period of time (at least 2 hours), and cool it in oil to 50-100°C and air cooling. The hardness can reach 50 after quenching. -52HRC, 200℃ low temperature tempering treatment should be carried out immediately to prevent cracking. After tempering, the hardness can be maintained above 48HRC

Salt bath vanadium infiltration treatment

The neutral salt bath vanadium treatment process of Crl2MoV cold work die steel. Crl2MoV steel can be treated with neutral salt bath vanadium to obtain a carbide layer. 1. Carbon vanadium compound. The layer has a uniform structure and good continuity. Compactness, uniform thickness, compact structure, high microhardness and high wear resistance, surface hardness, wear resistance and anti-adhesion properties are greatly improved. 2. The solubility of VC in austenite is higher than its solubility in ferrite. As the temperature decreases, VC precipitates from ferrite, which strengthens the alloy and refines the grains, and the compound layer shows higher The hardness. Cr12MoV is a high-carbon, high-chromium ledeburite steel with high carbide content, accounting for about 20%, and it is often unevenly distributed in bands or nets, with serious segregation, and it is difficult to change the situation of carbide segregation by conventional heat treatment. Affect the mechanical properties of steel and the service life of the mold. The shape and size of carbides also have a great impact on the performance of steel. In particular, the large sharp-angled carbides have a relatively large splitting effect on the steel matrix, and often become the source of fatigue fracture. For this reason, the raw material rolled steel must be Forging is changed to fully crush the eutectic carbides to make them small and uniformly distributed. The fiber structure is distributed around the cavity or non-oriented, thereby improving the transverse mechanical properties of the steel.

During forging, the billet is upset and drawn several times from different directions, and forging is carried out by the "two light and one heavy" method, that is, the billet should be lightly hit at the beginning of forging to prevent breakage. It can be hit hard at the intermediate temperature of 980~1 020 ℃. To ensure the crushing of carbides,

Cr12MoV steel has not been modified for forging, and adopts solid solution double refinement treatment [5], that is, two-stage preheating at 500 ℃ and 800 ℃, solution treatment at 1 100~1 150 ℃, quenching into hot oil or austempering, high temperature of 750 ℃ Tempering, heating and oil cooling at 960 ℃ after machining, and final heat treatment, can also refine carbide, rounded edges and grains.

Tempering specification

Recommended tempering specification for Cr12MoV steel

| Program | Quenching temperature /℃ | Temper | Quenching | ||

| Use | Heating temperature/℃ | medium | Hardness HBW | medium | Hardness HRC |

|

Ⅰ Ⅱ Ⅲ |

1020~1040 |

Stress relief Remove stress and reduce hardness Remove stress and reduce hardness |

150~170 200~275 400~425 |

Oil or salt— — |

61~63 57~59 55~57 |

|

Ⅳ Ⅴ Ⅵ |

1115~1130 |

Remove stress and form secondary hardening Remove stress and form secondary hardening Remove stress and form secondary hardening |

510~520℃ multiple tempering -78℃ cold treatment Temper at 510~520℃ once -78℃ cold treatment plus 510~520℃ tempering once, then -78℃ cold treatment |

— — — |

60~61 60~61 61~6 |

Quenching specification

General quenching and tempering specifications:

Quenching temperature 1000~1050℃, quenching oil or quenching gas, hardness ≥ 60HRC; tempering temperature 160~180℃, tempering time 2h, or tempering temperature 325~375℃, tempering times 2~3 times.

| Program | First preheating/℃ | Second preheating/℃ | Quenching temperature/℃ | Cool down | Hardness (HRC) | |||

| medium | Medium temperature/℃ | Cool in the medium | Subsequently | |||||

|

Ⅰ Ⅱ Ⅲ Ⅳ Ⅴ |

550~660 | 840~860 |

950~1000 1020~1040 1020~1040 1115~1130 1115~1130 |

oil oil Molten Nitrate oil Molten Nitrate |

20~60 20~60 40~55 20~60 40~45 |

To oil temperature To oil temperature 5~10min To oil temperature 5~10min |

Air cooling Air cooling Air cooling Air cooling Air cooling |

58~62 62~63 62~63 42~50 42~50 |

Note: 1. Schemes II and III are used for workpieces that require high mechanical properties and less deformation, such as threaded rollers, thread rolling boards, molds with complex shapes and impact loads, etc.;

2. Schemes IV and V are used for workpieces that require red hardness and wear resistance, but have poor mechanical properties and large dimensional deformation, such as hot stamping dies working below 450°C;

3. This kind of steel is very sensitive to decarburization. The salt bath for preheating and heating must be fully deoxidized before use; if it is heated in an ordinary electric furnace, the workpiece can be loaded into the box

Inside, it is filled with carburizing agent or pig iron powder (the workpiece may have a little carburization at this time, and the hardness can be increased by HRC1~2).

Table 2-3-1 Structure ratio in quenched state

| Quenching Program | Cool down | Carbide/% | Martensite/% | Austenite/% |

| Ⅰ、Ⅱ | Oil, nitrate | 12 | 73~68 | 20~23 |

Typical example

1) The steel can be used to make punches, dies, and inserts with complex shapes of blanking dies with a material thickness of >3mm. The recommended hardness is 58~62HRC for punching and 60~64HRC for cavities.

2) Used to make punches and dies that require high wear resistance in punching dies. The recommended hardness for punching molds is 60~62HRC, and the recommended hardness for concave molds is 62~64HRC.

3) It is used to make the die that requires tensile strength in the drawing die, and the recommended hardness is 62 ~ 64HRC.

4) Used to make punches, dies and inserts that require wear resistance and complex shapes in bending dies. It is recommended that the hardness is 60~64HRC when making the punch, and the hardness is 60~64HRC when making the concave mold.

5) Used to make punches and dies for cold extrusion of aluminum parts. The recommended hardness is 60~62HRC when making punches and 62-64HRC when making concave molds.

Cr12MoV inspection methods:

① Detection of its core element content and composition;

② Its wear resistance test, carbide level measurement, the hardness after quenching is less than the national standard requirement of HRC58;

Product key description, this is a very good product description, detailing our product use, product characteristics