- GB/T3077

- China

- Stock

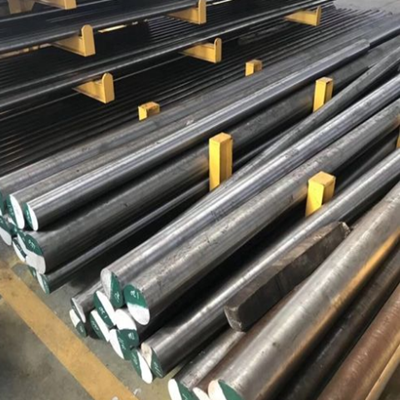

- 38CrMoAl steel

38CrMoAl steel 38crmoal is a high-grade nitrided steel with high wear resistance, high fatigue strength and high strength characteristics. Mainly used for nitrided parts with precise dimensions after heat treatment, or various nitrided part

38CrMoAl steel

38CrMoAl steel

38crmoal is a high-grade nitrided steel with high wear resistance, high fatigue strength and high strength characteristics. Mainly used for nitrided parts with precise dimensions after heat treatment, or various nitrided parts with low impact load and high wear resistance, such as boring bars, grinding machine spindles, automatic lathe spindles, worms, precision screw rods, precision gears, High-pressure valves, valve stems, gauges, templates, rollers, imitations, cylinder blocks, compressor piston rods, governors, rotating sleeves, fixed sleeves on steam turbines, various wear parts on rubber and plastic extruders, etc. .

Name: 38CrMoAl Steel

Standard: GB/T3077-2018

Round steel density: 0.00785g/mm^3

Properties: high wear resistance

Main uses: boring bar, grinding machine spindle, automatic lathe spindle, etc.

Standard: alloy steel pipe GB/T3077-2015, steel plate GB/T11251-2018.

Features and scope of application:

38CrMoAl has high surface hardness, wear resistance and fatigue strength, good heat resistance and corrosion resistance, and low hardenability. Used to produce nitrided parts with high wear resistance, high fatigue strength, considerable strength, and high dimensional accuracy after treatment, such as imitation molds, cylinder liners, gears, high-pressure valves, boring rods, worms, grinding machine spindles, etc. However, larger parts should not be used.

Chemical composition

| Grade | Chemical composition(%) | |||||||||

| C | Si | Mn | S | P | Cr | Al | Ni | Cu | Mo | |

| 38CrMoAl | 0.35~0.42 | 0.20~0.45 | 0.30~0.60 | ≤0.035 | ≤0.035 | 1.35~1.65 | 0.70~1.10 | ≤0.30 | ≤0.30 | 0.15~0.25 |

Physical properties

| Grade | Physical properties | ||||||

| Tensile strength (MPa) | Yield strength MPa) | Elongation (%) | rate of reduction in area (%) | Impact energy (J) | Impact toughness value (J/cm2) | Hardness(HB) | |

| 38CrMoAl | ≥980 | ≥835 | ≥14 | ≥50 | ≥71 | ≥88 | ≤229 |

Sample size: sample blank size is 30mm

Heat treatment specification

● Heat treatment specification and metallographic structure:

Heat treatment specification: quenching 940℃, water cooling, oil cooling; tempering 640℃, water cooling, oil cooling.

●Delivery status: delivery in (normalizing, annealing or high temperature tempering) or without heat treatment, the delivery status should be indicated in the contract.

● Annealing No.1 "760±10℃ annealing, furnace cooling to 400℃ air cooling.

Equivalent grade

| GB/T3077 | ISO | JIS | DIN | BS | NF |

| 38CrMoAl | 41CrAlMo74 | SACM645 | 41CrAlMo7 34CrAlMo5 | 905M39 905M31 | 40CAD6.12 30CAD6.12 |

38CrMoAl round steel bar specification

| Grade | Specifications Length (MM) | Weight | Alloy Steel | Product Name |

| 38CrMoAl | 3.0-25 | 50t | Alloy Steel | Bright Round Bar |

| 38CrMoAl | 12-50 | 50t | Alloy Steel | Hot Rolled Round Steel |

| 38CrMoAl | ф100-130 | 50t | Alloy Steel | Hot Rolled Round Steel |

| 38CrMoAl | ф140-150 | 50t | Alloy Steel | Hot Rolled Round Steel |

| 38CrMoAl | ф160-170 | 50t | Alloy Steel | Hot Rolled Round Steel |

| 38CrMoAl | ф16-40 | 50t | Alloy Steel | Hot Rolled Round Steel |

| 38CrMoAl | ф200-280 | 50t | Alloy Steel | Hot Rolled Round Steel |

| 38CrMoAl | ф50-70 | 50t | Alloy Steel | Hot Rolled Round Steel |

| 38CrMoAl | ф50-90 | 50t | Alloy Steel | Hot Rolled Round Steel |

| 38CrMoAl | ф50-95 | 50t | Alloy Steel | Hot Rolled Round Steel |

| Material | Specifications Length (Mm) | Fixed Rolling | Alloy Steel | Product Name |

| 38CrMoAl | 8-10 | 50t | Alloy Steel | Hot Rolled Steel Sheet |

| 38CrMoAl | 12-16 | 50t | Alloy Steel | Hot Rolled Steel Sheet |

| 38CrMoAl | 18-20 | 50t | Alloy Steel | Hot Rolled Steel Sheet |

| 38CrMoAl | 22-28 | 50t | Alloy Steel | Hot Rolled Steel Sheet |

| 38CrMoAl | 30-34 | 50t | Alloy Steel | Hot Rolled Steel Sheet |

| 38CrMoAl | 80-100 | 50t | Alloy Steel | Forged Steel Plate |

| 38CrMoAl | 160 | Fixed Rolling | Alloy Steel | Forged Steel Plate |

| 38CrMoAl | 170 | Fixed Rolling | Alloy Steel | Forged Steel Plate |

| 38CrMoAl | 180 | Fixed Rolling | Alloy Steel | Forged Steel Plate |

Product key description, this is a very good product description, detailing our product use, product characteristics