- JIS G3460

- China

- Stock

- STPL380

JIS G3460 STPL380 Steel tubes for piping used at particularly low temperature below freezing.JIS G3460 STPL380 Steel tubes usually applies to pipes with an outer diameter of 10.5 mm to 660.4 mm.

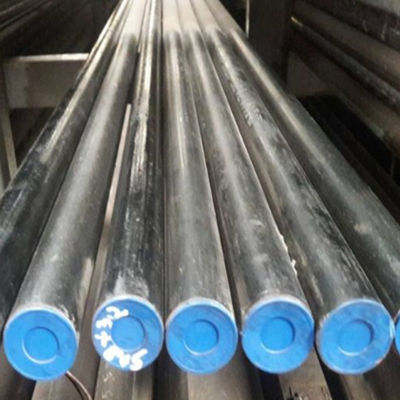

JIS G3460 STPL380 Seamless Steel Tubes

JIS G3460 STPL380 Seamless Steel Tubes

Standard:JIS G3460

Steel tubes for low temperature service

JIS G3460 STPL380 Steel tubes for piping used at particularly low temperature below freezing.

JIS G3460 STPL380 Steel tubes usually applies to pipes with an outer diameter of 10.5 mm to 660.4 mm.

JIS G3460 STPL380 Steel Tubes Quick Details

Manufacturing:Seamless; Electric resistance welding

Type:Hot finished,Cold finished,welded.

Wall thickness(WT): 12.7mm——50 mm.

Outer diameter (OD): 10.5mm——660.4mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished (Outside only) to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package:Standard export package,suit for all kinds of transport, or as required

Manufacturing method

The tube is made of fine-grained killed steel, STPL 380 is manufactured seamlessly or by electrical resistance welding.

The end of the pipe is plain end unless otherwise specified.

Heat treatment of JIS G3460 STPL380

| Grade | Heat treatment |

| STPL380 |

Normalized, Normalized, Post-tempered, Or quenching and tempering |

Chemical composition of JIS G3460 STPL380

|

Letter symbol of grade

|

Chemical Composition % | |||||

| C | Si | Mn | P | S | Ni | |

| STPL 380 | 0.25 max. | 0.35 max. | 1.35 max. | 0.035 max. | 0.035 max. | - |

Mechanical properties of JIS G3460 STPL380

| Letter symbol of grade | Mechanical properties | |||||

| Tensile strength | Yield point or proof stress | Elongation % | ||||

| kgf/mm2 {N/mm2} | kgf/mm2 {N/mm2} | No. 11 or No. 12 test piece | No. 5 test piece | No. 4 test piece | ||

| Longitudinal | Transverse | Longitudinal | Transverse | |||

| STPL 380 | 39 {382}min. | 21{206} min. | 35 min. | 25 min. | 30 min. | 22 min. |

Note 1N / mm2 = 1 MPa

Note) For tubes with an outside diameter of less than 40 mm, the elongation in this table does not apply.

Dimensional tolerances

Tolerances on Outside Diameter, Wall Thickness and Deviation in Wall Thickness

| Division | Tolerance on outside diameter |

Tolerance on wall thickness |

Tolerances on deviation in wall thickness |

| Hot-finished seamless steel pipe | Up to 50 mm 【 0.5mm | Up to 4mm【0.5mm | Within 20% of wall thickness |

|

50mm or over,【1% up to 160mm |

4mm and over【12.5% | ||

| 160mm and over,【1.6mm up to 200mm | |||

| 200mm or over 【 0.8% | |||

| However, for pipes 350mm or over in diameter, the length of circumference may be used as a bases for tolerance. In this case, the tolerances shall be 【 0.5% | |||

| Cold-finished seamless steel pipe, electric-resistance welded pipe | Up to 40mm 【 0.3mm | Up to 2mm【0.2mm |

- |

| 40mm and over 【 0.8% |

2mm and over【10% |

||

| However, for pipes 350mm or over in diameter, the length of circumference may be used as a bases for tolerances. In this case, the tolerance shall be 【 0.5 % |

Appearance

a) tube must be practical and straight and both ends are perpendicular to the tube axis.

b) the inner surface of the tube is good in finishing, and there is no defect which is harmful to use.

c) in the case of surface treatment, it may be necessary for grindstone or machining, but the thickness of the product after the care must be within the tolerance of thickness.

d) the ruins must be smoothly formed in the shape of the tube.

Testings

Analysis testing

Mechanical testing

Tensile testing

Flattening testing

Bending testing

Charpy impact testing

Hydraulic or non-destructive testing

Marking

a) type of symbol

b) a symbol representing a manufacturing method

The symbols representing the manufacturing method are as follows. However,-may be blank.

1) Hot finish seamless steel pipe -S-H

2) Cold finish seamless steel pipe -S-C

3) Electric resistance welded as-is steel pipe -E-G

4) Hot finish electric resistance welded steel pipe -E-H

5) Cold finish electric resistance welded steel pipe -EC

c) Dimensions. The dimensions indicate the nominal diameter and nominal thickness, or the outer diameter and thickness.

Example 50A × Sch40 or 60.5 × 3.9

d) Manufacturer name or its code

e) Symbol Z representing designation of special quality regulations (when designated)

Report

We will submit inspection documents to the order.

Product key description, this is a very good product description, detailing our product use, product characteristics