- GB/T 3639

- China

- Stock

- Grade 10、20、35、45

Standard: GB/T 3639 is applicable to the manufacture of mechanical structures, hydraulic equipment, automotive cold-drawn or cold-rolled precision seamless steel tubes with special dimensional accuracy and high surface quality requirements.

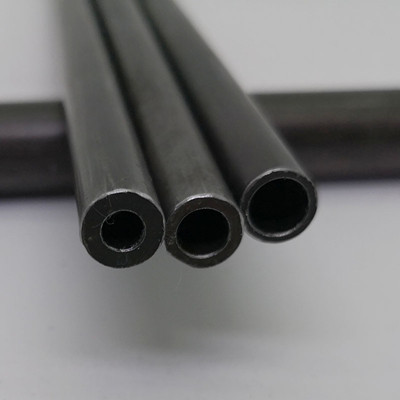

GB/T 3639 Cold-Drawn Or Cold-Rolled Precision Seamless Tubes

GB/T 3639 Grade 10、20、35、45、Cold-drawn or cold-rolled precision seamless tubes

Standard: GB/T 3639

This standard is applicable to the manufacture of mechanical structures, hydraulic equipment, automotive cold-drawn or cold-rolled precision seamless steel tubes with special dimensional accuracy and high surface quality requirements.

Main grades:

Grade 10, Grade 20, Grade 35, Grade 45

GB/T 3639 Cold-drawn or cold-rolled precision seamless tubes Quick Details

Company Name: Beite steel pipe

Country/Region: China

Main grades: Grade 10, Grade 20, Grade 35, Grade 45

FOB Price: US $900-1500 / Ton | 1 Ton/Tons (Min. Order)

Delivery Status: +BK, +BK W, +BK S, +GBK, +NBK

Port of Shipment: Tianjin, China

Payment: L/C or T/T

Delivery: 7-15 days after payment

Package:Standard export package,suit for all kinds of transport, or as required

Certificate: ISO 9001-2000, PED 97/23/EC, ASME, DNV

GB/T 3639 Cold-drawn or cold-rolled precision seamless tubes Dimensional Range & Specification

Outside Diameter: 4.0mm - 200.0mm

Wall thickness: 3.0mm - 12.5mm

Length: 6000mm, 12000m or specified length as required.

Manufacturing

The steel pipe is manufactured by cold drawn or cold rolled.

Steel pipe according to delivery status:

Cold working / hard (BK), cold working / soft (BK W), stress relief annealing after cold working (BK S), annealing (GBK), normalizing (NBK).

| Delivery status | Code | Description |

| Cold working / hard | B K | After the final cold working, no heat treatment is performed, so that the tube can only be deformed very little. |

| Cold working / soft | B K W | After the final heat treatment, a small amount of cold working is performed to allow limited cold deformation (for example, bending and flaring) when the steel pipe is reworked. |

| Stress relief annealing after cold working | B K S | After cold working, it is annealed below the Acl point to eliminate cold working stress. |

| Annealing | G B K | After the final cold working, the steel tube is completely annealed under a protective gas |

| Normalizing | N B K | After the final cold working, the normalizing of the steel pipe under protective gas |

Chemical composition of GB/T 3639

| No. |

Uniform numeric code |

Designation | Chemical composition (mass fraction)/% | |||||||

|

C |

Si |

Mn |

P | S | Cr | Ni | Cu a | |||

| ≤ | ||||||||||

| 2 | U20102 | 10 | 0.07~0.1 3 | 0.17~0.37 | 0.35~0.65 | 0.035 | 0.035 | 0.15 | 0.30 | 0.25 |

| 4 | U20202 | 20 | 0.17~0.23 | 0.17~0.37 | 0.35~0.65 | 0.035 | 0.035 | 0.25 | 0.30 | 0.25 |

| 7 | U20352 | 35 | 0.32~0.39 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.30 | 0.25 |

| 9 | U20452 | 45 | 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | 0.035 | 0.035 | 0.25 | 0.30 | 0.25 |

| Any element not specified in this table shall not be added without agreement of the users. Measures shall be taken to prevent steel scrap or other materials from bringing in element which influences performance of steels. | ||||||||||

| a Copper content for steel used for hot press working shall not be greater than 0.20%; | ||||||||||

Physical properties of GB/T 3639

| Grade | Delivery status | ||||||||||

| B K | B K W | B K S | G BK | N B K | |||||||

|

Tensile strength, Mpa |

Elongation, % |

Tensile strength, Mpa |

Elongation, % |

Tensile strength, Mpa |

Elongation, % |

Tensile strength, Mpa |

Elongation, % |

Tensile strength, Mpa |

Yield Strength |

Elongation, % |

|

| ≥ | |||||||||||

| 10 | 410 | 6 | 375 | 10 | 335 | 12 | 335 | 24 | 335 | 205 | 24 |

| 20 | 510 | 5 | 450 | 8 | 430 | 10 | 390 | 20 | 410 | 245 | 20 |

| 35 | 590 | 4 | 550 | 6 | 520 | 8 | 510 | 17 | 530 | 315 | 17 |

| 45 | 645 | 4 | 630 | 5 | 610 | 7 | 590 | 14 | 600 | 355 | 14 |

| Note: For steel pipes with an outer diameter of not more than 30 mm and a wall thickness of more than 3 mm, the minimum yield point can be reduced by 10 MPa. | |||||||||||

The end of Precision seamless steel pipe

The end faces of the steel pipe should be perpendicular to the axis of the steel pipe, and the burrs of the cut should be removed.

Testings:

Dimensional inspection: The size and shape of the steel pipe are measured and inspected one by one using a measuring tool that meets the accuracy.

Surface quality: The inner and outer surfaces of the steel pipe shall be visually inspected one by one under conditions of sufficient illumination.

Chemical composition: Take 1 sample per furnace number for chemical composition testing.

Tensile test: Take 1 sample per batch for tensile test.

Compactness test: The GB/T 3639 steel pipe is tested one by one

Surface roughness inspection: Each sample is taken on each of 2 steel pipes for inspection.

Tag example

Cold-rolled precision seamless steel pipe made of 20 steel with an outer diameter of 50 mm and an inner diameter of 30 mm, cold worked/hard state, marked as:

Finishing 20-∅50X ∅ 30BK-GB/T 3639- 2017

Cold-rolled precision seamless steel pipe made of 10 steel with an outer diameter of 38 mm, a wall thickness of 3 mm and a length of 5 000 mm, cold worked/soft state, marked as:

Finishing 10-∅38 X 3 X 5000BKW-GB/T 3639- 2017

Cold drawn precision seamless steel pipe made of 35 steel with an inner diameter of 30 mm, a wall thickness of 2 mm and a length of 1 800 mm, and a stress-relieving annealing state, marked as:

Fine extraction 35- inner ∅30 X 2 X 1 800 BKS-GB/T 3639- 2017

Product key description, this is a very good product description, detailing our product use, product characteristics