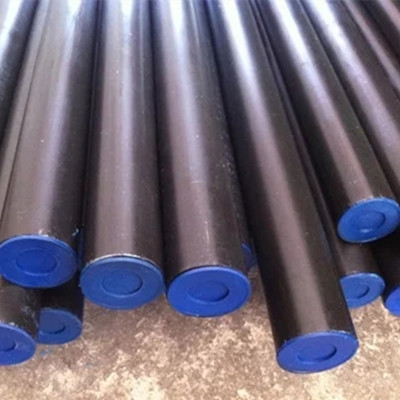

EN 10305-1 E235 Cold Drawn Precision Seamless Tubes

- EN 10305-1

- China

- Stock

- E215,E235,E355

EN 10305-1 E235 for seamless cold drawn steel tubes of circular cross section for precision applications with specified outside diameter D ≤ 380 mm

EN 10305-1 E235 Cold Drawn Precision Seamless Tubes

EN 10305-1 E235 Seamless cold drawn tubes

EN 10305-1 E235 Steel tubes for precision applications - Technical delivery conditions - Part 1: Seamless cold drawn tubes

EN 10305-1 E235 Seamless cold drawn tubes Quick Details

Company Name: Beite steel pipe

Country/Region: China

Material:E235

FOB Price: US $1500-3000 / Ton | 1 Ton/Tons (Min. Order)

Port of Shipment:Tianjin,China

Payment:L/C or T/T

Delivery: 7-15 days after payment

Package:Standard export package,suit for all kinds of transport, or as required

EN 10305-1 E235 Seamless cold drawn tubes Dimensional Range & Specification

Outside Diameter:4mm-260mm

Wall thickness:0.5mm——25mm

Length:6000mm、12000m or specified length as required.

EN 10305-1 E235 Seamless cold drawn tubes

Standard:EN 10305-1

EN 10305-1 E235 for seamless cold drawn steel tubes of circular cross section for precision applications with specified outside diameter D ≤ 380 mm.

Tubes according to the EN 10305-1 are characterized by having precisely defined tolerances on dimensions and a specified maximum surface roughnes

Manufacturing process

The steelmaking process is at the discretion of the manufacturer with the exception that the open hearth (Siemens-Martin) process shall not be employed unless in combination with a secondary steelmaking or ladle refining process.

Steels shall be fully killed.

NOTE This excludes the use of rimming, balanced or semi-killed steel.

Tube manufacture and delivery conditions

The tubes shall be manufactured from hot finished seamless hollows by cold drawing.

The tubes shall be supplied in one of the delivery conditions given in Table 1.

Table 1 — Delivery conditions

| Designation | Symbol a | Description |

| Cold drawn / hard | +C | No final heat treatment after final cold drawing. |

| Cold drawn / soft | +LC | Final heat treatment is followed by a suitable drawing pass (limited reduction of area) |

| Cold drawn and stress relieved | +SR | After final cold drawing the tubes are stress relieved in a controlled atmosphere. |

| Soft annealed | +A | After final cold drawing the tubes are soft annealed in a controlled atmosphere |

| Normalized | +N | After final cold drawing the tubes are normalized in a controlled atmosphere. |

| a:In accordance with EN 10027–1 | ||

Chemical composition of EN 10305-1 E235 Seamless cold drawn tubes

Option 1: A steel grade not specified in this document, with a maximum total content of alloying elements of 5 % and agreed chemical composition, mechanical properties and delivery condition, is specified.

Table 2 — Chemical composition (cast analysis)

| Steel grade | % by mass | ||||||

| Steel name | Steel number | C max. | Si max. | Mn max | P max. | S ,a max | Al,total b min |

| E235 | 1.0308 | 0,17 | 0,35 | 1,20 | 0,025 | 0,025 | 0,015 |

| Elements not quoted in this table (but see footnote b ) shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for the purposes of deoxidation and/or nitrogen binding. All appropriate measures shall be taken to prevent the addition of undesirable elements from scrap or other materials used in the steel making process. | |||||||

|

a :See option 2. b :This requirement is not applicable provided the steel contains a sufficient amount of other nitrogen binding elements, such as Ti, Nb or V. If added, the content of these elements shall be reported in the inspection document. When using titanium, the manufacturer shall verify that (Al + Ti/2) ≥ 0,020. |

|||||||

Option 2: For the steel grades E235 a controlled sulphur content of 0,015 % to 0,040 % is specified to support machinability. It shall be obtained by resulphurizing the steel after maximum desulphurization or alternatively by using a low oxygen process.

Option 3: The chemical composition of the specified steel grade shall be such that it is suitable for hot-dip galvanizing (see e.g. EN ISO 1461 or EN ISO 14713-2 for guidance).

Mechanical properties of EN 10305-1 E235

NOTE Subsequent processing (cold or hot) may change the mechanical properties.

Table 3 — Mechanical properties at room temperature

| Steel grade | Minimum values for the delivery condition a | ||||||||||||

| +C b | +LC b | +SR | +A c | +N | |||||||||

| Steel name | Steel number | R m (MPa) | A % | R m (MPa) | A % | R m (MPa) | R eH (MPa) | A % | R m (MPa) | A % | R m (MPa) |

R eH d (MPa) |

A % |

| E235 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 350 | 16 | 315 | 25 | 440 to 480 | 235 | 25 |

|

a ,R m : tensile strength; R eH : upper yield strength (but see 11.1); A: elongation after fracture. For symbols for the delivery condition see Table 1. b ,Depending on the degree of cold work in the finishing pass the yield strength may nearly be as high as the tensile strength. For calculation purposes the following relationships are recommended: — for delivery condition +C: R eH ≥ 0,8 R m ; — for delivery condition +LC: R eH ≥ 0,7 R m. c ,For calculation purposes the following relationship is recommended: R eH ≥ 0,5 R m . d ,For tubes with outside diameter ≤ 30 mm and wall thickness ≤ 3 mm the R eH minimum values are 10 MPa lower than the values given in this table. e ,For tubes with outside diameter > 160 mm: R eH ≥ 420 MPa. |

|||||||||||||

Summary of testing

Chemical analysis

Tensile test

Dimensional inspection

Visual examination

Flattening test or drift expanding test

Roughness measurement

NDT on longitudinal imperfections

NDT for verification of leak tightness

we can supply different materials for EN10305-1 tubes as a cold drawn seamless pipe, expecially S355 steel tube,EN 10305-1 E235+C cylinder tubes.

Product key description, this is a very good product description, detailing our product use, product characteristics