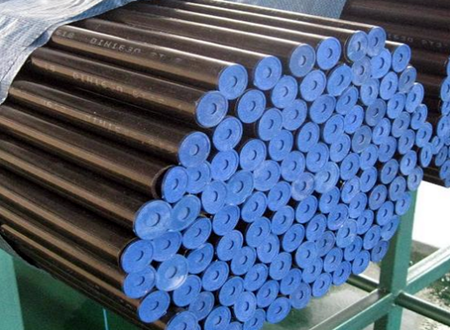

DIN 2391 ST45 Seamless Precision Steel Tube

- DIN 2391

- China

- Stock

- ST45

DIN 2391 St45 Seamless Precision steel tubes are mainly used where accuracy to dimension and, possibly, small wall thicknesses and good surface condition are required.

DIN 2391 ST45 Seamless Precision Steel Tube

DIN 2391 St45 Seamless Precision Steel Tube

Standard:DIN 2391 Part 2

DIN 2391 St45 Seamless Precision steel tubes according to this Standard are mainly used where accuracy to dimension and, possibly, small wall thicknesses and good surface condition are required.

DIN 2391 St45 Seamless Precision Steel Tube Quick Details

Company Name: Beite steel pipe

Country/Region: China

Material:St45

FOB Price: US $1800-2600 / Ton | 1 Ton/Tons (Min. Order)

Port of Shipment:Tianjin,China

Payment:L/C or T/T

Delivery: 7-15 days after payment

Package:Standard export package,suit for all kinds of transport, or as required

DIN 2391 St45 Seamless Precision Steel Tube Dimensional Range & Specification

Outside Diameter:4.0mm——43.0mm

Wall thickness:1.0mm——8.0mm

Length:6000mm、12000m or specified length as required.

Quality grade

The tubes are supplied in the following quality grades:

A :precision steel tubes intended primarily for mechanical stressing, without any particular quality requirement and without acceptance test certificate

B :precision steel tubes intended primarily for mechanical stressing, with special quirement and exclusively with acceptance test certificate

C :precision steel tubes with special requirement according to section 12. Theses requirements and corresponding tests must be agreed, with the customer having to specify his requirements at the time of enquiry and on ordering

Steel grades

Table 1. Steel grades

| Quality grade | Steel grade | |

| Code number | Material number | |

| A and B |

St 30 Si St 30 Al St 35 St 45 St 52 |

1.0211 1.0212 1.0308 1.0408 1.0580 |

| C | All steel grades according to quality grade A and B, as well as other steels, e.g. according to | |

|

DIN 1651 DIN 17 100 DIN 17 200 |

DIN 17 210 DIN 17 211 |

|

Chemical composition of DIN 2391 St45 Seamless Precision Pipe

Table 2. Steel grades and chemical composition of the steels

| Steel grade | Chemical composition, % | |||||

| Symbol | Material number | C max | Si max | Mn | P max | Smax |

| St 45 | 1.0408 | 0.21 2) | 0.35 | ≥ 0.40 | 0.050 | 0.050 |

|

1) This steel is deoxidized using aluminum. 2) In subsequent testing on the individual tube, the C-content must not exceed 0.25%. |

||||||

Condition on delivery

The tubes are supplied in one of the conditions listed in table 3. Other conditions on delivery are specified in table 5 (quality grade C).

Table 3. Conditions on delivery

| Term | Symbol | Explanation |

|

Cold-finished/hard (cold-finished as-drawn) |

BK |

No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

|

Cold-finished/soft (lightly cold-worked) |

BKW |

After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

Mechanical properties of DIN 2391 St45 Seamless Precision Pipe

Table 4. Mechanical properties of the tubes at room temperature

| Steel grade | Condition on delivery | |||||||||

|

Cold-finished/hard (BK) 3) |

Cold-finished/soft (BKW) 3) |

Annealed (GBK) 3) |

Normalized (NBK) |

|||||||

|

Code number |

Material number |

Tensile strength Rm N/㎟ min |

Elongation at repture A5(%) min |

TensiLe strength Rm N/㎟ min |

Elongation at repture A5(%) min |

Tensile strength Rm N/㎟ min |

Elongation at repture A5(%) min |

Tensile strength Rm N/㎟ |

Upper yield point ReH N/㎟ min |

Elongation at repture A5(%) min |

| St 45 | 1.0408 | 540 | 5 | 470 | 8 | 390 | 21 | 440 to 570 | 255 | 21 |

|

3) The yield point for the annealed (GBK)condition on delivery is at least 50% of the (ultimate) tensile strength. Depending upon the degree of deformation in the drawing operation, the yield point of tubes delivered in the cold-finished/hard (BK)and cold-finished/soft(BKW) conditions, may be increased to a level close to the tensile strength. In calculating the yield point, the following values are recommended : cold-finished/hard condition on delivery ≥ 80% of the tensile strength, cold-finished/soft condition on delivery ≥ 70% of the tensile strength. 4) In the case of tubes of outside diameter ≤ 30 mm, the wall thickness of which is ≤ 3mm, the minimum value of the yield point is 10 N /㎟ lower. |

||||||||||

Quality grade C:

Table 5 Special requirements(examples)

| Line | Special requirement | Features and/or technical delivery conditions |

| 1 | Steel grades other than specified in table 1 | As specified in DIN 1651,DIN EN 10025,DIN EN 10083 Parts 1 and 2,or DIN 17210 |

| 2 | Tubes for pipelines | As specified in DIN 1629,DIN1630,or DIN 2445 Part 2 |

| 3 | Other geometry and surface |

Tubes with an outside diameter smaller than 4 mm and greater than 260 mm, with a non-circular cross section,subject to other tolerances than those specified in DIN 2391 Part 1, other tolerance positions or special requirements regarding the surface condition,stralghtness and squareness of pipe ends |

| 4 | Final supply condition other than specified in table 3 | Tempered;annealed to obtain speciflc microstructure |

| 5 | Other mechanical properties | Deviations regarding the mechanical properties specified in table 4 |

Testings

Tensile test

Flattening test

Moasurement of surface roughness

Dimensional check

Surface inspection

Leal tightness test

Non-destructive test

Product key description, this is a very good product description, detailing our product use, product characteristics