ASTM A556 Grade C2 Seamless Cold-Drawn Feedwater Heater Tube

- ASTM A556

- China

- Stock

- Grade C2

ASTM A556 Grade C2 Steel Tubes covers minimum-wall-thickness,seamless cold-drawn carbon steel tubes including bending into the form of U-tubes, for use in tubular feedwater heaters.

ASTM A556 Grade C2 Seamless Cold-Drawn Feedwater Heater Tube

ASTM A556 Grade C2 Seamless Cold-Drawn Feedwater Heater Tubes

Standard:ASTM A556/A566M

Standard Specification for Seamless Cold-Drawn Carbon Steel Feedwater Heater Tubes

ASTM A556 Grade C2 Steel Tubes covers minimum-wall-thickness,seamless cold-drawn carbon steel tubes including bending into the form of U-tubes, for use in tubular feedwater heaters.

ASTM A556 Grade C2 Seamless Cold-Drawn Feedwater Heater Tubes sizes covered shall be 5 ⁄ 8 to 1 1 ⁄ 4 -in. [15.9 to 31.8-mm] outside diameter, inclusive, with minimum wall thicknesses equal to or greater than 0.045 in. [1.1 mm].

ASTM A556 Grade C2 Cold-Drawn Feedwater Heater Tubes Quick Details

Company Name: beite steel pipe

Country/Region: China

Product Name:ASTM A556 Grade A2 Feedwater Heater Tubes

Manufacture:Seanmless And Cold drawn.

Outside Diameter:15.9mm——38.1mm

Wall thickness:1.1mm——5mm

Length:6000mm、12000m or specified length as require

Port of Shipment:Tianjin,China

Payment:L/C or T/T

Delivery: 7-15 days after payment

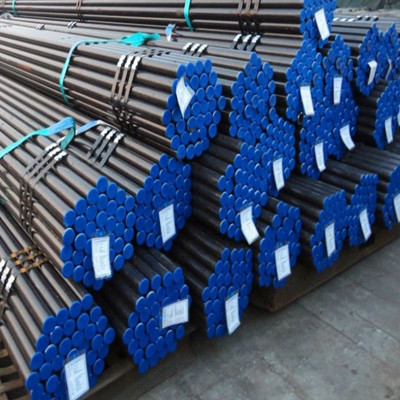

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden)

Manufacture

ASTM A556 Grade C2 Seamless Cold-Drawn Feedwater Heater Tubes are made by the seamless process and shall be cold drawn.

Heat Treatment:

ASTM A556 Grade C2 Seamless Cold-Drawn Feedwater Heater Tubes are heat treated after the final cold-draw pass at a temperature of 1200°F [640°C] or higher to ensure ductility satisfactory for rolling into tube sheets and to meet mechanical properties as specified.

If stress-relief anneal of the U-bends is specified, the anneal shall consist of heating the bent portion within a range of 1100 to 1200°F [585 to 640°C].

Chemical Composition

| Element | Composition, % |

| Grade C2 | |

| Carbon, max | 0.30 |

| Manganese | 0.27–1.06 |

| Phosphorus, max | 0.035 |

| Sulfur, max | 0.035 |

| Silicon, min | 0.10 |

Mechanical Properties

| Grade C2 | |

| Tensile strength, min, ksi [MPa] | 70 [480] |

| Yield strength, min, ksi [MPa] | 40 [280] |

|

Elongation in 2 in. or 50 mm, min, % (longitudinal)

|

35 |

| Hardness | HR B 89 |

Tolerances of ASTM A556 Grade C2 Feedwater Heater Tubes

|

Hot finished

|

OD +/- 1%

|

WT +/-12.5%

|

|

Cold finished

|

OD +/-0.75%

|

WT +/-10%

|

Mechanical Tests

Tension Test

Flattening Test

Flaring Test

Hardness Test

Hydrostatic Test

Packaging

Bundles (hexagonal),

Wooden Boxes,

Crates (steel/wooden)

The tubing be packaged or bundled in such a manner as to prevent damage in ordinary handling and transportation and identified by a tag with the name of the manufacturer, purchase order number, specification number and grade, and size.

Ordering Information

1 Orders for material include the following as required to describe the desired material adequately:

1.1 Quantity (feet, metres, or number of pieces),

1.2 Name of material (seamless steel tubing),

1.3 Dimensions (outside diameter and minimum wall thickness),

1.4 Length (specific or random),

1.5 Manufacture (cold drawn),

1.6 Grade (chemical composition),

1.7 Test report required

1.8 Specification number, and

1.9 Special requirements and any supplementary requirements selected.

Product key description, this is a very good product description, detailing our product use, product characteristics