- ASTM A213/ASME SA213

- China

- Stock

- T2

A213 T2 Seamless Steel Tube can prevent the tendency of graphitization, after long-term use at 480-540 ℃, the mechanical properties and microstructure are stable enough, and the pipe processing and welding properties are good.

ASTM A213 T2 Alloy Steel Seamless Tubes

ASME SA213 T2 Seamless Steel Tubes

SA213 T2 is the steel grade in ASME SA213M standard. It is a 1 / 2cr-1 / 2Mo type steel developed on the basis of 1 / 2Mo steel. It is a ferritic hot strength steel for boiler and superheater.

SA213 T2 steel is close to 12CrMoG of GB5310 in China. Because the steel contains chromium, which can prevent the tendency of graphitization, after long-term use at 480-540 ℃, the mechanical properties and microstructure are stable enough, and the pipe processing and welding properties are good.

Equivalent steel grade

| Standard | Grade |

| ASME SA213 | SA213 T2 |

| GB5310 | 12CrMoG |

ASTM A213 T2 Seamless Steel Tubes Quick Details

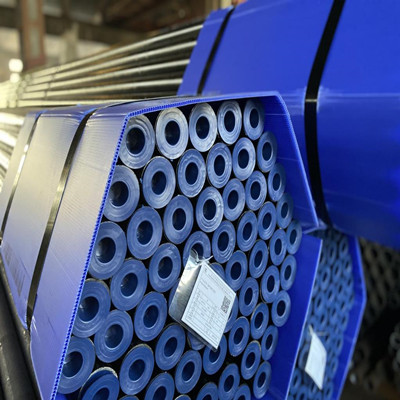

Manufacture:Seamless process ,Hot-finished or Cold-finished

Wall thickness(WT): 0.9 mm——12.7 mm.

Outer diameter (OD): 12.7 mm——127 mm

Length: 6M or specified length as required.

Ends: Plain End, Beveled End, Treaded

Additional Info

Port of Shipment: Tianjin, China

Payment Terms:T / T, LC

Delivery: 7-15 days after payment

Surface: Tubes will be varnished (Outside only) to prevent rust.

Marking: Standard + Steel Grade + Size + Heat No + Lot No

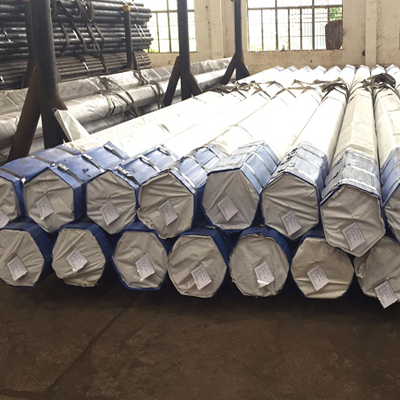

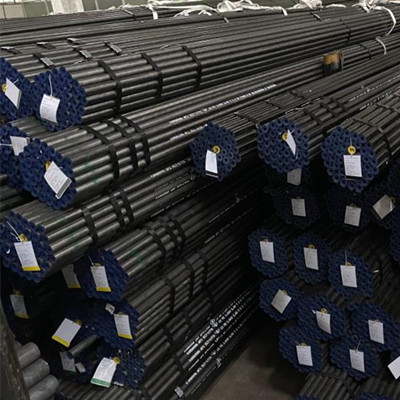

Package: Bundles (hexagonal),Wooden Boxes,Crates (steel/wooden) or as required

Application of ASME SA213 T2 seamless steel tubes

SA213 t2asme SA213 T2 seamless steel tubes are mainly used for superheater and reheater system with working temperature lower than 540 ℃, and also for water wall tube in supercritical boiler

Chemical composition (%)

| Grade | Chemical composition | ||||||

| C | Si | Mn | P | S | Cr | Mo | |

| SA213 T2 | 0.10-0.20 | 0.10-0.30 | 0.30-0.61 | ≤0.025 | ≤0.025 | 0.50-0.81 | 0.44-0.65 |

| 12CrMoG | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 | 0.40-0.70 | 0.40-0.55 |

Metallographic structure

The delivery state of ASME SA213 T2 seamless steel tubes are normalizing and tempering, and the microstructure is ferrite + sorbite.

Mechanical properties

Mechanical properties at room temperature

| Grade | Mechanical properties at room temperature | |||

| Tensile strength | Yield strength | Elongation | HardnessHB(HRB) | |

| SA-213 T2 | ≥ 415 | ≥205 | ≥ 30 | ≤163(85) |

| 12CrMoG | 410-560 | ≥205 | ≥21 | |

Oxidation resistance

SA213 T2 steel is mainly used in Superheater and reheater system with working temperature lower than 540 ℃, and its oxidation resistance is better than that of carbon steel and carbon manganese steel.

Welding performance

SA213 T2 steel has good welding performance, generally it can be annealed at 650 ~ 700 ℃ after welding without preheating. Heat 207 for manual welding rod and h12crmo / jgs-1cm for GTAW.

Tubes bending

ASME SA213 T2 seamless steel tubes are suitable for all kinds of bending processes. After cold bending, it needs to be de stressed; when the temperature of hot bending exceeds the tempering temperature, it should be re normalized and re ignited.

Images of ASTM A213 ASME SA213 T2 Seamless Steel Tubes

Product key description, this is a very good product description, detailing our product use, product characteristics