ASTM A210 Grade C Seamless Boiler Tube

- ASTM A210

- China

- Stock

- Grade C

ASTM A210 Grade C Medium-Carbon Steel Seamless Boiler Tube

ASTM A210 Grade C Seamless Boiler Tube

ASTM A210 Grade C Medium-Carbon Steel Seamless Boiler Tube

ASTM A210/A210M for Seamless Medium-Carbon Steel Boiler and Superheater Tubes.

ASTM A210 Grade C boiler tube suitable for seamless tube with minimum wall thickness.

ASTM A210 Grade C Boiler Tube Quick Details

Company Name: beite steel pipe

Country/Region: China

Product Name:ASTM A210 Grade C Boiler Tube

FOB Price: US $1000-2000 / Ton | 1 Ton/Tons (Min. Order)

Port of Shipment:Tianjin,China

Payment:L/C or T/T

Delivery: 7-15 days after payment

Package:Standard export package,suit for all kinds of transport, or as required

Certificate:ISO 9001-2000,PED 97/23/EC,ASME,DNV

ASTM A210 Grade C Boiler Tube Dimensional Range & Specification

Outside Diameter:12.7mm——127mm

Wall thickness:0.9mm——12.7mm

Length:6000mm、12000m or specified length as required.

Manufacture

The tubes shall be made by the seamless process and shall be either hot-finished or cold-finished, as specified.

Heat Treatment

Hot-finished tubes need not be heat treated. Cold- finished tubes shall be given a subcritical anneal, a full anneal, or a normalizing heat treatment after the final cold finishing process.

Surface Condition

Pickling or shot blasting, Passivated, Black Phosphating.

For tensile and hardness test requirements, the term “lot” applies to all tubes prior to cutting, of the same nominal diameter and wall thickness which are produced from the same heat of steel. When final heat treatment is in a batch-type furnace, a lot shall include only those tubes of the same size and the same heat which are heat treated in the same furnace charge. When the final heat treatment is in a continuous furnace, a lot shall include all tubes of the same size and heat, heat treated in the same furnace at the same temperature, time at heat, and furnace speed.

ASTM A210 Grade A1&C Boiler Tube Chemical Composition(%)

| Standard | Grade | chemical composition: | ||||

| C | Si | Mn | P | S | ||

| ASTM A210 | A-1 | ≤0.27 | ≥0.10 | ≤0.93 | ≤0.035 | ≤0.035 |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | |

ASTM A210 Grade A1&C Boiler Tube Mechanical & Physical Properties

| Standard | Grade | Tensile Strength(MPa) | Yield Strength(MPa) | Elongationδ(%) | ||

| ASTM A210 | A-1 | ≥ 415 | ≥ 255 | ≥30 | ||

| C | ≥485 | ≥275 | ≥30 | |||

For flattening and flaring requirements, the term “lot” applies to all tubes prior to cutting of the same nominal size and wall thickness which are produced from the same heat of steel. When final heat treatment is in a batch-type furnace, a lot shall include only those tubes of the same size and from the same heat which are heat treated in the same furnace charge. When the final heat treatment is in a continuous furnace, the number of tubes of the same size and from the same heat in a lot shall be determined from the size of the tubes as prescribed in Table 2.

TABLE 2 Number of Tubes in a Lot Heat Treated by the Continuous Process

| Size of Tube | Size of Lot |

|

2 in. (50.8 mm) and over in outside diameter and

0.200 in. (5.1 mm) and over in wall thickness

|

not more than 50 tubes |

|

2 in. (50.8 mm) and over in outside diameter and

under 0.200 in. (5.1 mm) in wall thickness

|

not more than 75 tubes |

|

Less than 2 in. (50.8 mm) but over 1 in. (25.4

mm)in outside diameter

|

not more than 75 tubes |

| 1 in. (25.4 mm) or less in outside diameter | not more than 125 tubes |

For tensile and hardness test requirements, the term “lot” applies to all tubes prior to cutting, of the same nominal diameter and wall thickness which are produced from the same heat of steel. When final heat treatment is in a batch-type furnace, a lot shall include only those tubes of the same size and the same heat which are heat treated in the same furnace charge. When the final heat treatment is in a continuous furnace, a lot shall include all tubes of the same size and heat, heat treated in the same furnace at the same temperature, time at heat, and furnace speed.

Hardness Requirements

The tubes shall have a hardness not exceeding the following: 79 HRB or 143 HB for Grade A-1, 89 HRB or 179 HB for Grade C.

Mechanical Tests Required

Tension Test—One tension test shall be made on a specimen for lots of not more than 50 tubes. Tension tests shall be made on specimens from two tubes for lots of more than 50 tubes .

Flattening Test—One flattening test shall be made on specimens from each end of one finished tube from each lot (see Note 2), but not the one used for the flaring test. Tears or breaks occurring at the 12 or 6 o’clock positions on Grade C tubing with sizes of 2.375 in. [60.3 mm] in outside diameter and smaller shall not be considered a basis for rejection.

Flaring Test—One flaring test shall be made on speci- mens from each end of the one finished tube from each lot (see Note 2), but not the one used for the flattening

Hardness Test—Brinell or Rockwell hardness tests shall be made on specimens from two tubes from each lot (see Note 3).

Hydrostatic or Nondestructive Electric Test—Each tube shall be subjected to the hydrostatic, or, instead of this test, a nondestructive electric test may be used when specified by the purchaser.

We can customize and innovate the ASTM A210 Grade C Boiler Tube with advanced technology. Our all ASTM A210 Grade C Boiler Tube are tested in accordance to internationally recognized standards or our own more stringent internal test procedures, which is developed considering the harsh field conditions. Tension test, flattening test, flaring test, hardness test, hydrostatic or nondestructive electric test be made on specimens.

ASTM A210 Grade C Boiler Tube Outside Diameter & Tolerance

| Hot rolled | ||||||||||

| Outside Diameter, mm | Tolerance, mm | |||||||||

| OD≤101.6 | +0.4/-0.8 | |||||||||

| 101.6<OD≤127 | +0.4/-1.2 | |||||||||

| Cold Drawn | ||||||||||

| Outside Diameter, mm | Tolerance, mm | |||||||||

| OD<25.4 | ±0.10 | |||||||||

| 25.4≤OD≤38.1 | ±0.15 | |||||||||

| 38.1<OD<50.8 | ±0.20 | |||||||||

| 50.8≤OD<63.5 | ±0.25 | |||||||||

| 63.5≤OD<76.2 | ±0.30 | |||||||||

| 76.2≤OD≤101.6 | ±0.38 | |||||||||

| 101.6<OD≤127 | +0.38/-0.64 | |||||||||

ASTM A210 Grade C Boiler Tube Wall thickness & Tolerance

| Hot rolled | ||||||||||

| Outside Diameter , mm | Tolerance, % | |||||||||

| OD≤101.6, WT≤2.4 | +40/-0 | |||||||||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |||||||||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |||||||||

| OD≤101.6, WT>4.6 | +28/-0 | |||||||||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |||||||||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |||||||||

| OD>101.6, WT>4.6 | +28/-0 | |||||||||

| Cold Drawn | ||||||||||

| Outside Diameter , mm | Tolerance, % | |||||||||

| OD≤38.1 | +20/-0 | |||||||||

| OD>38.1 | +22/-0 | |||||||||

ASTM A210 Grade C Boiler Tube Packaging & Delivery

Types of Packaging:

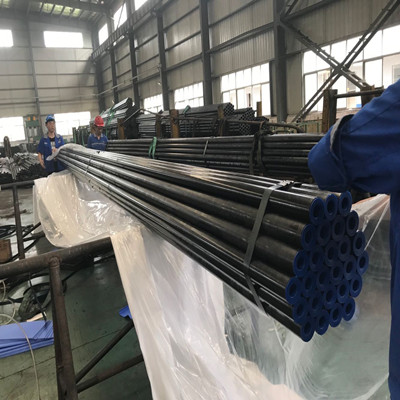

- Bundles (hexagonal)

- Wooden Boxes

- Crates (steel/wooden)

- Special crates for U-Bend tubes with each radius separated

- Our ASTM A210 Grade C Boiler Tube packing can meet any needs of the customers.

Delivery: 7-15 days after payment

Our(beite steel pipe) advantages

1.Our ASTM A210 Grade C Boiler Tube has been strictly tested.

2.We have a large number of ASTM A210 Grade C Boiler Tube stocks.

3.Our delivery time is very short

4.Quote within 12 hours

5.Our factory has only one hour's journey to the port

Product key description, this is a very good product description, detailing our product use, product characteristics