JIS G3455 Carbon Steel Pipes for High Pressure Service

JIS G3455 Carbon Steel Pipes for High Pressure Service

1. Scope

This Japanese Industrial Standard specifies the carbon steel pipes, hereinafter referred to as the "pipes" , used for high pressure service at an approximate maximum temperature of 350℃

Remarks

1. With the previous agreement of the manufacturer, the purchaser may designate part or all of the supplementary quality requirements Z2, Z3 ,Z4 and Z5 specified in this text.

Appendix Z 2: Elevated Temperature Yield Point or Proof Stress

Appendix Z 3: Ultrasonic Examination

Appendix Z 4: Eddy Current Examination

Appendix Z 5: Charpy Impact Test

2. The units and numerical values given un { } in this Standard are based on the International System of Units (SI) and are appended for informative reference.

Further, the traditional units accompanied by numerical values in this Standard shall be converted to the SI units and numerical values on Jan. 1, 1991.

2. Grade and Designation

Steel Grade: STS 370 ,STS 410 ,STS 480

Steel Grade: STS 370 ,STS 410 ,STS 480

The pipe shall be classified into three grades and their letter symbols shall be as given in Table 1

Table 1 Steel Grade Of JIS G3455 Carbon Steel Pipes

| Letter symbol of grade | (Informative reference) Traditional symbol |

| STS 370 | STS 38 |

| STS 410 | STS 42 |

| STS 480 | STS 49 |

3. Method of Manufacture

Appearance shall be as follows:

3.1 The pipe shall be manufactured from killed steel by the seamless process

3.2 The pipe shall be subjected to the heat treatment specified in Table 2. The heat treatment other than those specified in Table 2 shall be agreed upon by the purchaser and the manufacturer.

Table 2 Heat treatment

| Letter symbol of grade | Hot-finished seamless steel pipe | Cold-finished seamless steel pipe |

| STS 370 |

As manufactured. However, low temperature annealing of normalizing

may be applied, as necessary.

|

Low temperature annealed of normalized |

| STS 410 | ||

| STS 480 | Low temperature annealed of normalized | |

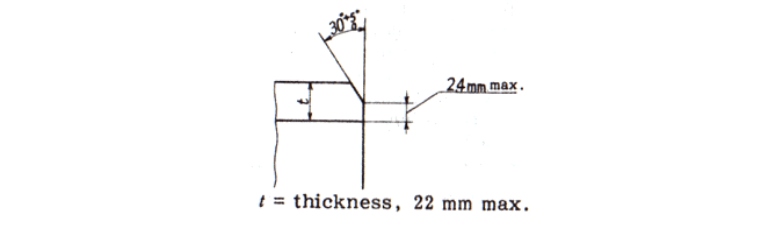

3.3 When required by the purchaser, the pipe may be furnished with a bevel end (2)

Note (2)Unless otherwise specified, the shape of the bevel end shall be as shown in Fig. 1.

4. Chemical Composition

Table 3 Chemical Composition Of JIS G3455 Carbon Steel Pipes

| Grade | Chemical Composition % | ||||

| C | Si | Mn | P | S | |

| STS 370 | 0.25 max. | 0.10~0.35 | 0.30~1.10 | 0.035 max. | 0.035 max. |

| STS 410 | 0.30 max. | 0.10~0.35 | 0.30~1.40 | 0.035 max. | 0.035 max. |

| STS 480 | 0.33 max. | 0.10~0.35 | 0.30~1.50 | 0.035 max. | 0.035 max. |

5. Mechanical Properties

Tensile Strength, Yield Strength or Proof Stress and Elongation

Table 4 Mechanical Properties Of JIS G3455 Carbon Steel Pipes

| Letter symbol of grade | Mechanical Properties | |||||

| Tensile strength | Yield strength | Elongation % | ||||

| kgf/m㎡ {N/ m㎡} | kgf/m㎡ {N/ m㎡} | No.11 and No.12 test pieces | No. 5 test pieces | No. 4 test piece | ||

| Longitudinal | Transverse | Longitudinal | Transverse | |||

| STS370 | 38 {373}min | 22{216} min | 30 min | 25 min | 23 min | 28 min |

| STS 410 | 42{412}min | 25{245} min | 25 min | 20 min | 19 min | 24 min |

| STS 480 | 49{481} min. | 28{275} min. | 25 min. | 20 min. | 17 min. | 22 min. |

Remarks

1. When the tensile test is carried out for No. 12 of No. 5 test piece for the pipe under 8mm in wall thickness, the minimum value of elongation shall be obtained by subtracting 1.5% from the values of elongation given in Table 3-2 for each 1 mm decrease in wall thickness, and rounding off to an integer in accordance with JIS Z 8401 Examples of calculation are given in Informative Reference Table.

2. The value of elongation given in Table 3-2 shall not be applied to the pipe whose nominal outside diameter is under 40 mm. However, the value of elongation shall be recorded.

Informative Reference Table 4-1.

Examples of Elongation Values Calculated for No. 12 Test Piece (Longitudinal) and No. 5 Test Piece (Transverse) for pipes under 8 mm in Wall Thickness

| Letter symbol of grade | shape of test piece | Elongation value relating to wall thickness % | ||||||

|

Over 7mm

to and excl.8mm

|

Over 6mm

to and excl7mm

|

Over 5mm

to and excl.6mm

|

Over 4mm

to and excl. 5mm

|

Over 3mm

to and excl. 4mm

|

Over 2mm

to and excl. 3mm

|

Over 1mm

to and excl. 2mm

|

||

| STS 370 | No12 test piece | 30 | 28 | 27 | 26 | 24 | 22 | 21 |

| No5. test piece | 25 | 24 | 22 | 20 | 19 | 18 | 16 | |

|

STS 410 STS 480 |

No12 test piece | 25 | 24 | 22 | 20 | 19 | 18 | 16 |

| No5. test piece | 20 | 18 | 17 | 16 | 14 | 12 | 11 | |

5.2 Flatness

When tested in accordance with 9.3, the pipe shall not generate flaws of cracks on its wall surface.

In this case, the distance between the two plates shall be in accordance with the following formula:

Where

H : distance between flattening plates (mm)

t : wall thickness of pipe (mm)

D : outside diameter of pipe (mm)

e : constant individually defined for each grade of pipe, 0.08 for STS 38 0.07 for STS 42 and STS 49

5.3 Bending

For the pipe whose outside diameter is 50mm of smaller, the purchaser may specify the bending test instead of the flattening test. In the test of 9.4, the pipe shall be free form

the occurrence of flaws or cracks on its wall surface. In this case, the pipe shall be bent through 90ⅹ around an inside radius that is 6 times its outside diameter.

6. Hydrostatic Characteristic of Nondestructive Characteristic

The pipe shall be tested in accordance with 9.5 and the resulting hydrostatic characteristic of nondestructive characteristic shall conform to either of the following two. The preference for which of them shall be left to specification by the purchaser or to the discretion of the manufacturer.

6.1 Hydrostatic Characteristic (Applicable to the end of 1990) When a hydrostatic pressure that is specified by the purchaser, of in the absence of that specification, the values given in Attached Table 1 is applied, the pipe shall withstand is without leakage, In this case, the purchaser, may specify a value of pressure lower or higher than those given in

Attached Table 1.

In a hydrostatic pressure test designated by the purchaser, a test pressure exceeding either the value of P calculated from the following formula or 200kgf/Р{196bar} shall be agreed upon by the purchaser and the manufacturer. In this case, the hydrostatic test pressure shall be expressed in each 5 kgf/Р {4.9 bar} and its multiples, and in calculation.the value P in the following formula shall be obtained to the number of units and rounded off to the nearest 5kgf/Р{4.9 bar}.

P=200st / D

Where

P: test pressure [ kgf/Р{10 -1 bar( 2 )}

t: wall thickness of pipe (mm)

D: outside diameter of pipe(mm)

s: 60% of the minimum value of yield point or proof stress specified in Table 3-1 [kgf/mm 2 {N/mm 2 }]

Note (1) 1bar = 10 5 Pa

6.2 Nondestructive Examination Characteristic

A nondestructive examination by either an ultrasonic test or an eddy current test shall be made on the pipe, and there shall be no signal greater than those produced by the artificial defects of the reference test block of division UD of the working sensitivity specified in JIS G 0582 or of division EY of the working sensitivity specified in JIS G 0583.

7. Appearance

Appearance shall be as follows:

7.1 The pipe shall be practically straight, and its both ends shall be at right angles to its axis.

7.2 The inside and outside surfaces of the pipe shall be well-finished and free from defects that are detrimental to practical use.

8.Dimensions, Weight and Dimensional Tolerances

8.1 Dimensions and Weight

The outside diameter, wall thickness and mass of the pipe shall be as specified in Attached Table 5.

8.2 Dimensional Tolerances

The tolerances on the outside diameter, wall thickness and wall thickness deviation of the pipe shall conform to Table5.

In the case where the pipe length is designated, the value shall be the minimum length.

Table 5. Tolerances on Outside Diameter, Wall Thickness and Wall Thickness Deviation

| Division | Tolerances on outside diameter | Tolerances on wall thickness |

Tolerances on wall thickness

deviation

|

|

Hot-finished seamless steel pipe

|

50mm Under 【0.5mm |

≤4mm Under

+0.6mm

-0.5mm

≤4mm or over

+15%

-12.5%

|

Within 20%

of wall thickness

|

|

50mm or over 200mm to and excl.

【1.6mm

|

|||

| 200mm of over 【0.8% | |||

|

For the pipe 350mm of over, the tolerances on outside diameter may be determined by the

measurement of the length of circumference. shall be 【0.5%.

|

|||

|

Cold-finished seamless steel pipe

|

40mm Under【0.3mm |

≤2mm Under

【0.2mm

|

- |

| 40mm of over 【0.8% |

≤2mm or over 【10% |

||

|

For the pipe 350mm or over, the tolerances on outside diameter may be determined by the

measurement of the length of circumference, In this case, the tolerances shall be 【0.5%.

|

Remarks

1. The wall thickness deviation means the ratio of the difference between the maximum and the minimum of the wall thickness measured in the same section the specified wall thickness, The wall thickness deviation shall not be applied to the pipe under 5.6mm in wall thickness.

2. When the length of circumference is used in measuring the outside diameter, either the measured value of the length of circumference of the diameter derived form the measured value may be used as the criteria, In both cases, the same value (【0.5%) of tolerances shall be applied. The diameter (D) and the length of circumference (ラ) shall be calculated reversibly from the following formula.

ラ=ヰ · D

where ヰ=3.1416

3. In the case where the tolerances on wall thickness are confirmed to meet the specifications in the above table, the tolerances on outside diameter in the above table shall not be applied to the local part being subjected to repairing, etc.

9. Test

9.1 Chemical analysis

9.1.1 Chemical Analysis

General matters common to chemical analysis and method of sampling specimens for analysis shall be in accordance with 3. in JIS G 0303.

9.1.2 Analytical Method

The analytical method shall be in accordance with one of the following Standards:

JIS G 1253

JIS G 1256

JIS G 1257

JIS G 1214

JIS G 1215

JIS G 1211

JIS G 1212

JIS G 1213

9.2 Tensile Test

9.2.1 Test piece

The test specimen shall be No. 11, No. 12A , No. 12B, No. 12C No. 4 or No.5 test piece specified in JIS Z 2201 and shall be sampled from a pipe. In this case, the gauge length for No. 4 test piece shall be 50 mm.

9.2.2 Test Method

The test specimen shall in accordance with JIS Z 2241

9.3 Flattening Test

9.3.1 Test piece

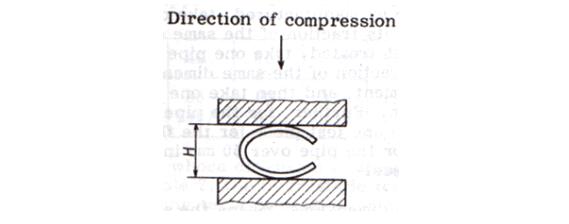

A test piece 50 mm or over in length shall be cut off from the end of a pipe. From the pipe whose wall thickness is 15% and over of the outside diameter, a C-shape test piece may be prepared by removing a part of the circumference of the full-section test piece may be used.

9.3.2 Test Method

The test piece shall be placed between two flat plates at ordinary temperatures and flattened by compression until the distance fence of flaws or cracks on its wall surface. In this case, the C-shape test piece shall be placed as shown in Fig. 2.

9.4 Bending Test

9.4.1 Test Piece

A test piece with an appropriate length shall be cut off from the end of a pipe.

9.4.2 Test Method

The test piece shall be bent at ordinary temperature through the angle around a cylinder with the inside radius specified in 4,3 and examined for the occurrence of flaws of cracks on its wall surface.

9.5 Hydrostatic Test of Nondestructive Examination

The hydrostatic test of non destructive examination shall be in accordance shall be in accordance with one of the following:

9.5.1 When the pipe is subjected to hydrostatic pressure and kept under the specified pressure, its strength to withstand the pressure without leakage shall be examined.

9.5.2 The test method of nondestructive examination shall be in accordance with either JIS G 0582 or JIS G 0583.

10. Inspection

Inspection shall be as follows:

10.1 General matters common to inspection shall be in accordance with JIS G 0303.

10.2 The chemical composition, mechanical properties, hydrostatic characteristic of nondestructive characteristic, dimensions and appearance shall conform to the requirements specified in 3., 4., 5., 6., and 7. However, appropriate nondestructive examination other than those specified in 9.5(2) may substitute as agreed upon by the purchaser and the manufacturer. Further, when the supplementary quality requirements given in Appendix are specified by agreement between the purchaser and the manufacturer, the results of inspection shall conform to the requirements specified in Z2, Z3, Z4 ofZ5.

10.3 Either the hydrostatic test of the nondestructive examination shall be performed for each pipe.

10.4 The number of specimens for the product analysis shall be as agreed upon by the purchaser and the manufacturer.

10.5 The method of sampling test specimens and the number of test pieces for tensile test and flattening test of bending test shall be as follows, For the pipe as-manufactured,take one pipe as the specimen from each 50 pipes of its fraction of the same dimensions( 3 ) , while for the pipe to be heat-treated, take one pipe as the specimen form each 50 pipes or its fraction of the same dimensions( 3 ) and of the concurrent heat treatment, and than take one tensile test piece from the test specimen. Further, for the pipe up under 50mm in outside diameter, take one test piece for the flattening test of the bending test, while for the pipe over 50mm in outside diameter, take one flattening test piece.

Note ( 3 ) The term "same dimensions" means the same outside diameter as well as the same wall thickness.

11.Reinspection

The pipe may be determined for final acceptance by a retest requirements of 4.4 JIS G 0303.

12. Marking

Each pipe having passed the inspection shall be marked with the following items. However, the smaller pipes of other pipes specified by the purchaser may be bundled together and marked for each bundle by a suitable means. In both cases, the order of arranging the marked items is not specified.

When approved by the purchaser, part of the items may be omitted.

(1) Letter symbol of grade

(2) Letter symbol indicating the manufacturing process(4)

(3) Dimensions( 5 )

(4) Manufacture’s name or its identifying brand

(5) Letter symbol Z indicating the supplementary quality specification

Notes ( 4 )

The letter symbol indicating the manufacturing process shall be as follows, provided that the dash may be omitted leaving a blank.

Hot-finished seamless steel pipe - S - H

Cold-Finished seamless steel pips - S - C

Note ( 5 )

The dimensions shall be expressed as follows:

Nominal dia. x nominal wall thickness or outside dia. x wall thickness

Example : 50A 】Sch 80

Example : 50A 】Sch 80

13. Report

The manufacturer shall, as a rule, submit to the purchaser the report carrying the test results, method of manufacture, ordered dimensions, quantity and work lot number traceable to the manufacturing conditions, etc.